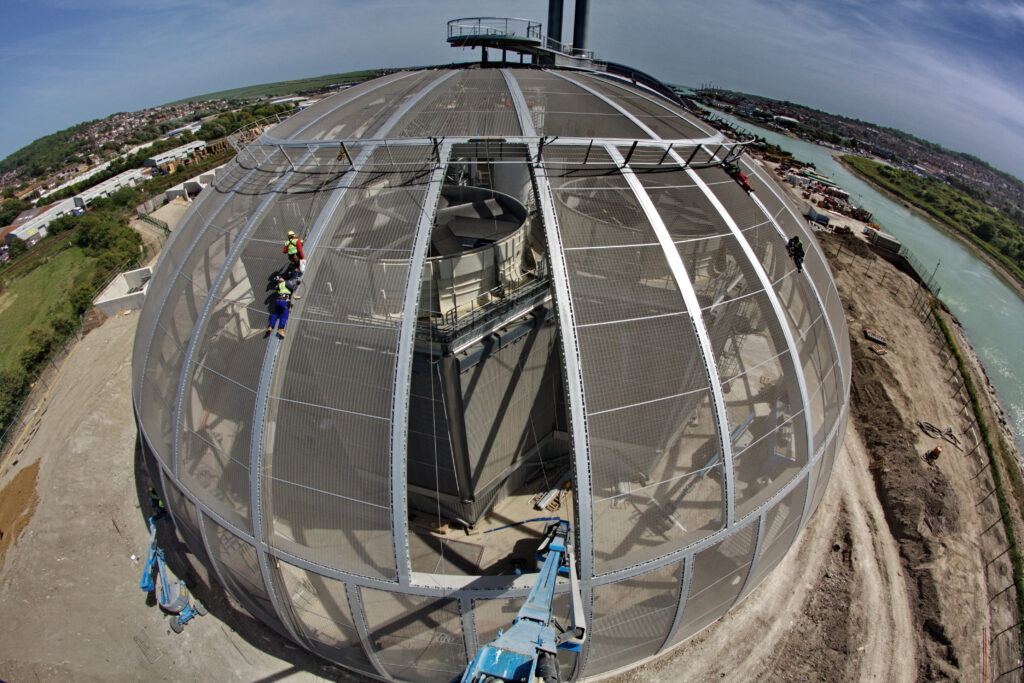

Base Structures were asked to tender for the fitting of a screen to minimize and soften the industrial visual impact of the cooling section built at the rounded northern end of the new £140 million Energy Recovery Facility (ERF). When operational this new ERF will take receipt of some 210,000 tonnes of municipal solid waste each year, to be treated in two boilers. The challenge to Base Structures was to install a suitable screening for the air-cooled condenser area: a 54 m diameter half dome on the northern end of the Newhaven ERF which needed to obfuscate the harsh detail of the externally mounted cooling equipment and yet would allow the necessary volume of air through it.

Delivering a structural solution required us to develop a fully engineered aluminium fabric clamping detail that would complement the inherent flexibility of the fabric thereby ensuring that the daily stresses and strains imposed on these very large wind catching sails would dissipate uniformly into the enclosing skeletal steel frame.

“We hit upon the idea of a ‘wavy’ clamping system,” says Base Structures’ Head of Projects, Mark Smith, “using an aluminium extrusion which allowed us to pass the load evenly through the steel, rather than through the PVC. We made a series of different prototypes until we evolved a fully engineered design that achieved the loads necessary.”

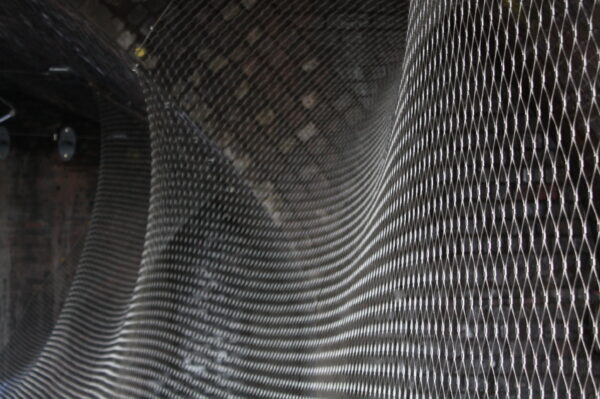

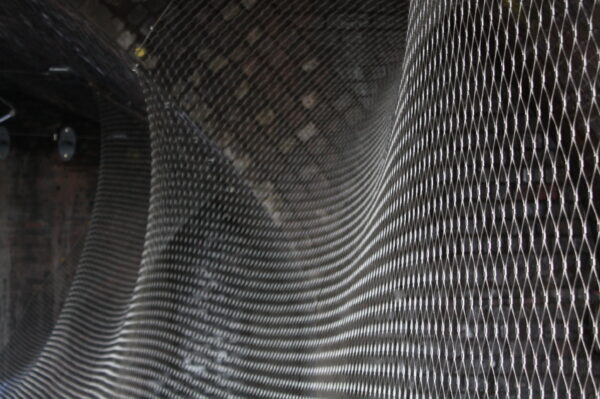

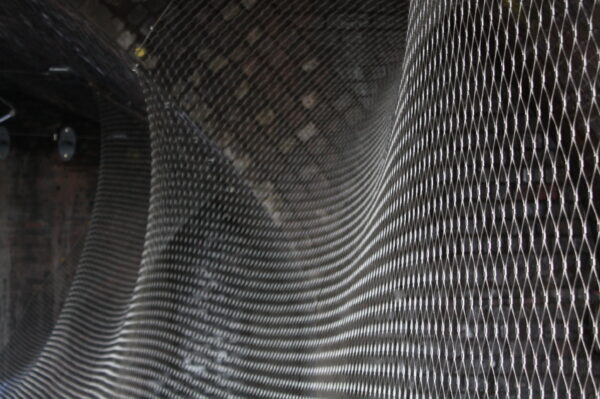

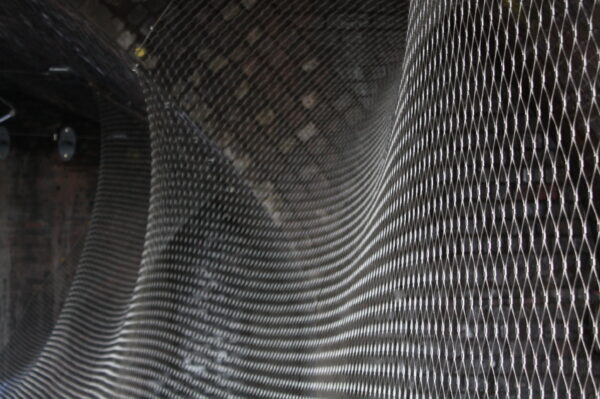

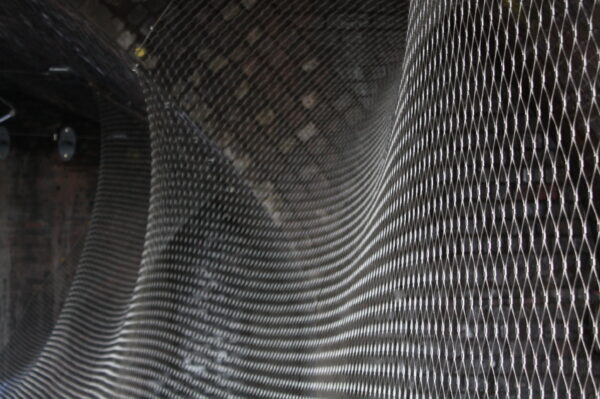

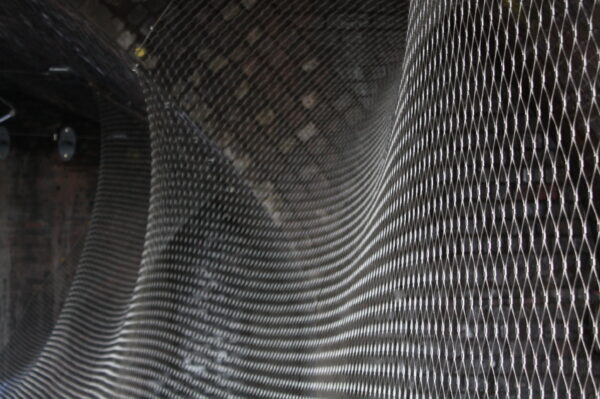

The architect identified a 50% open mesh fabric as delivering on these functional criteria. To enable this relatively light weight architectural mesh material to perform structurally it contains galvanised steel threads which are woven through it to a regular pattern.

Two different clamps were developed: an ‘intermediate’ design to hold the sections of fabric together, and a ‘perimeter’ design, used to clamp the joined sections to the supporting steel structure. The only modification necessary was to pre-stress the mesh before it was clamped in.

Installation of the mesh above the heavy process equipment took around six weeks for a team of six on the ground fitting sections together and 14 riggers, clamping and bolting the sections into place. Having refined this techique, Base Structures is confident it will significantly reduce this build time for future projects.

Like a vision taken straight from the set of Blade Runner, East Sussex’s new Energy Recovery Facility perches in the estuary of the River Ouse reclaiming the energy stored within our waste which would otherwise end up as landfill.

“Base Structures found a technical solution on the basis of their knowledge, creativity and problem solving attitude. They transferred successfully the information from design study onto the final construction.”

Andreas Clausen, HOCHTIEF Construction Manager

The annual Commercial Vehicle Show at Birmingham’s NEC is a big event. Many brands use this show to reveal their latest vans, which is why Ford the UK’s Commercial Vehicle leaders, wanted to showcase their latest big-budget advertising campaign.

NEC contacted Base Structures and asked us to remove two existing banners from the vehicle entry doors on Halls 1 & 5 either side of the main entrance and replace them with two of Ford’s new striking fabric advertisement pieces.

We manufactured and installed the 15 metres by 10 metres advertisement banners which have nestled in perfectly within our 3D fabric facades, a previous project commissioned last year.

Base were asked to design, manufacture and install the branch frame canopy including the supporting steel structure, fabric membrane and associated fittings.

This fabric canopy forms part of the refurbished entrance to the Multi Storey Car Park at Gatwick Airport. It not only provides protection for car park patrons when using the ticket machines but also serves as an attractive architectural feature to enhance the surroundings.

We designed, manufactured and installed a series of high level tensile fabric barrel vault canopies over the existing walkways surrounding the building.

With the addition of two dynamic, four cornered hypar sails over the entrance, an otherwise unremarkable new building becomes an elegantly land marked feature on the cityscape.

We were commissioned to design, fabricate and install a fabric covered walkway structure as part of the courtyard landscape at the Medicentre.

The tensile structure, which consists of five fabric sails supporting steel structure and integral lighting, provides shelter to patients traversing between two buildings as well as being an attractive addition to the courtyard. When lit up in the evening, the structure creates a very dramatic effect which the client is very pleased with.

The Nursery Pavilion at Lords Cricket Ground was constructed in 1999 to provide a venue for match day hospitality. Overlooking the Nursery Ground which is used by players to warm up before a match, the pavilion was in need of refurbishment. The brief was for a direct replacement following the exact same roof line, in order to meet planning constraints.

Thanks to innovations in tensile fabric, Base was able to suggest replacing the original 18 piece fabric structure with a single piece design, eliminating the need for the original unsightly metal clamps and speeding up the manufacturing and installation process.

The resulting canopy is a five cone tensile structure using 1900m2 of architectural PVC fabric, requiring an unusual five crane lift for installation. Base’s role included removal of the old pavilion fabric canopy, the detail design, manufacture and the installation of the new replacement. We also oversaw the refurbishment of structural steel and a flat roof structure.

Following our previous works to the Grandstand blinds, the Lords team asked us to carry out a condition survey of the truss steelwork, in doing so it was agreed that the structure required a full redecoration.

We designed a full painting specification along with all the necessary works. We attended site to clean the steelwork truss, columns, tie rods and flagpoles before project managing the redecoration works by specialist painting contractors.

The results have been well received and the structure has a new lease of life.

Following our previous works to the Lords Grandstand louvre blinds, we were approached to replace some tired ETFE cushions with a cost effective substitute. We were happy to assist and advised a bespoke solution for the new roof-lights to the grandstand which were in great need of improvement.

We developed a roof-light scheme that comprised of a series of polycarbonate roof light panels allowing natural light through whilst still providing thermal and weather protection. Importantly, for sporting arenas such as Lords, the specialist matt finish (Softlite) on the polycarbonate suppressed glare and ensures maximum visual comfort. We designed, supplied and installed the roof-light panels, sub frames and associated fixings.

Our brief was to install a series of commercial fabric canopies to the payment kiosks at the London Eye as well as the coffee shop.

These tensile structures provide shelter and sun shade whilst adding a dynamic visual attraction to this busy tourist area.

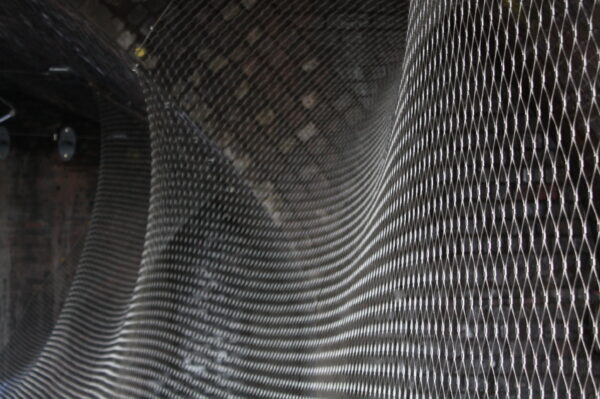

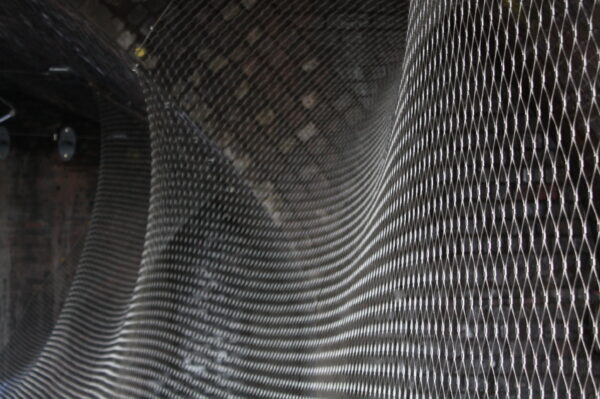

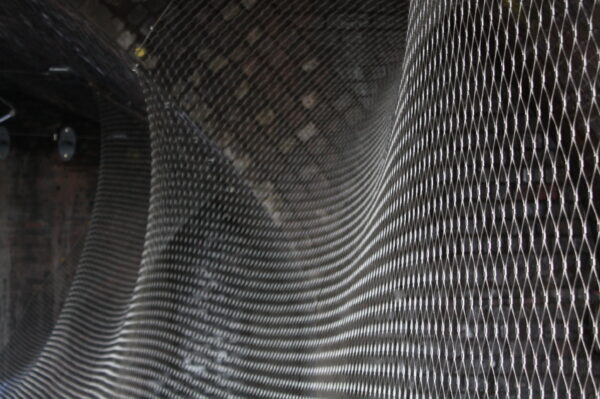

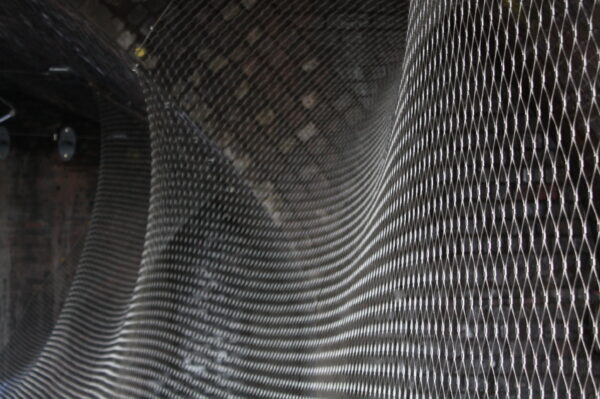

As part of our ongoing involvement with the London 2012 Games, working at the Velodrome under the direction of the renowned Hopkins Architects, Base Structures designed, manufactured and installed the interior air permeable mesh screens to the rear of the seating upper tier.

The PVC coated polyester mesh screen is visually continuous around the whole bowl, varying in height and gradient as it fills the void between the seating ‘bleachers’ and the curved roof. The screen serves two purposes in that it hides the air management ducting from view and also provides fall protection from the rear of the precast seating units.

The panels are held in place by a system of extruded aluminium tracks and stainless steel cables, which are in turn connected to the structural steel work and precast concrete seat units through a series of galvanised mild steel intermediate brackets.