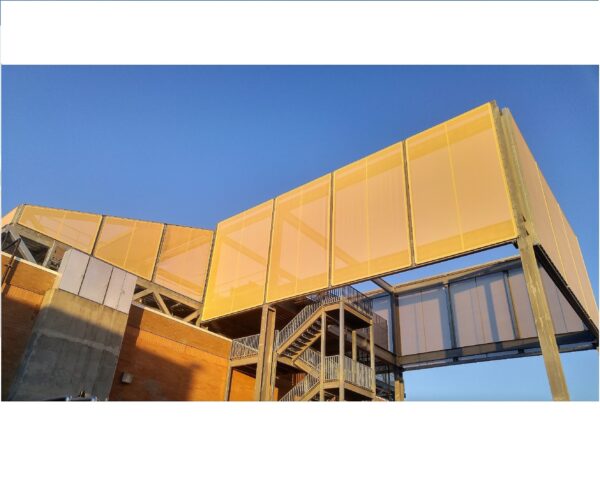

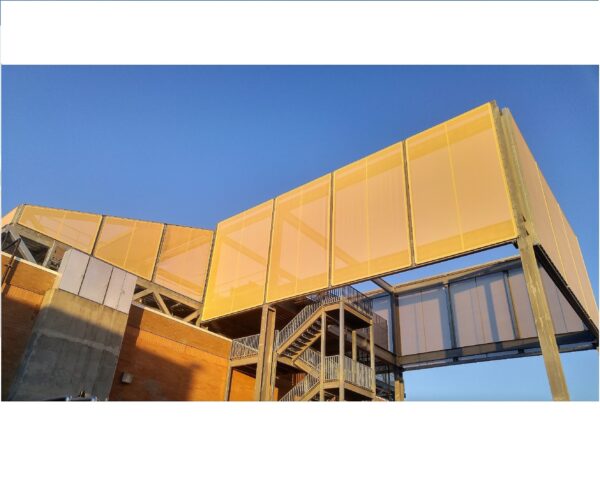

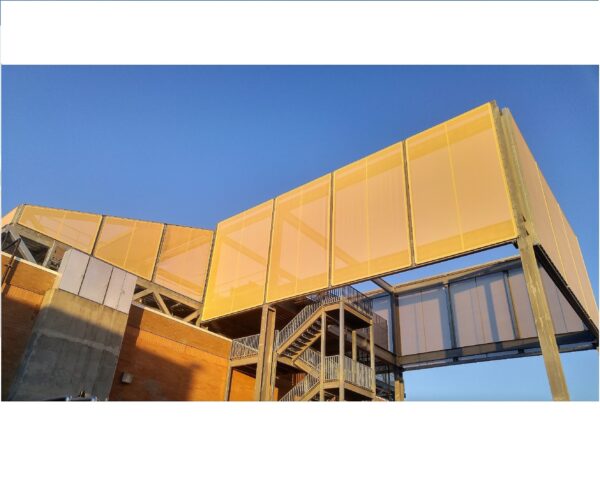

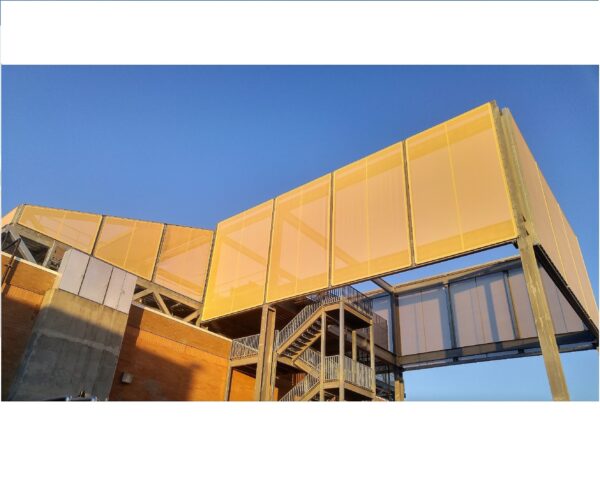

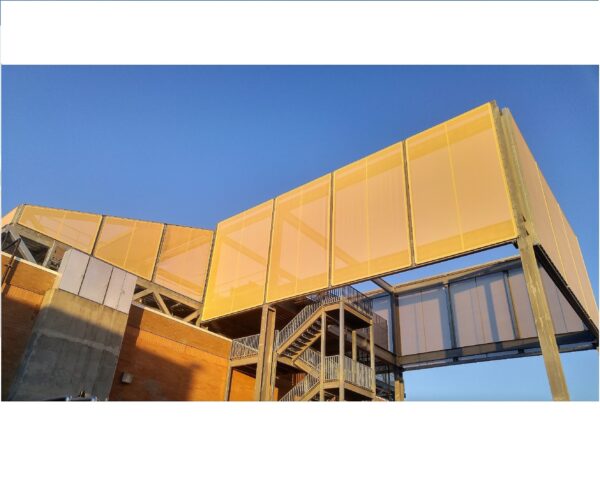

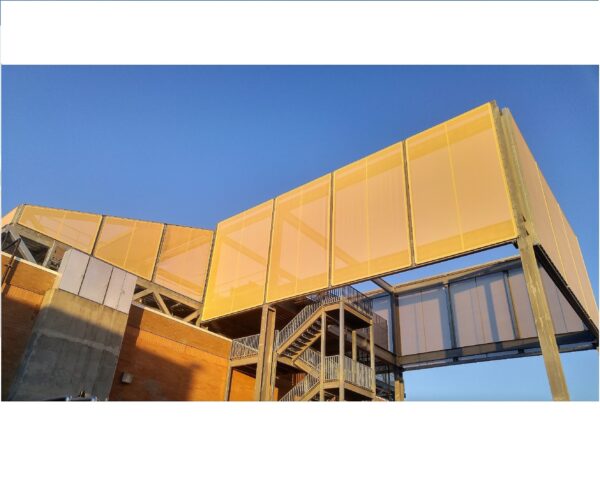

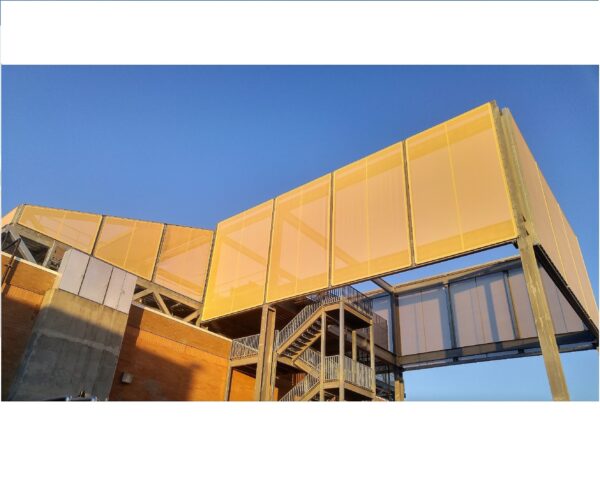

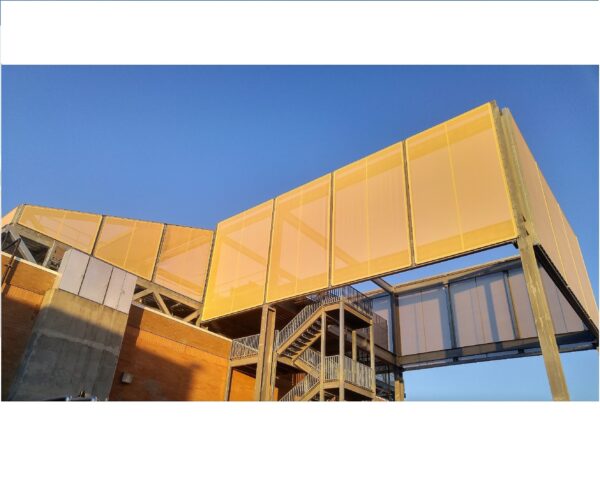

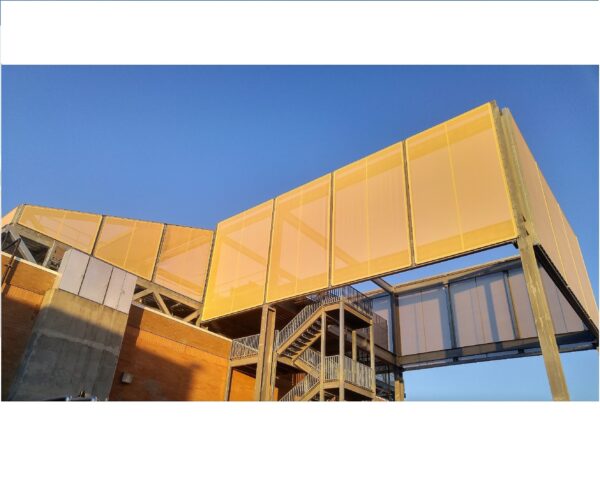

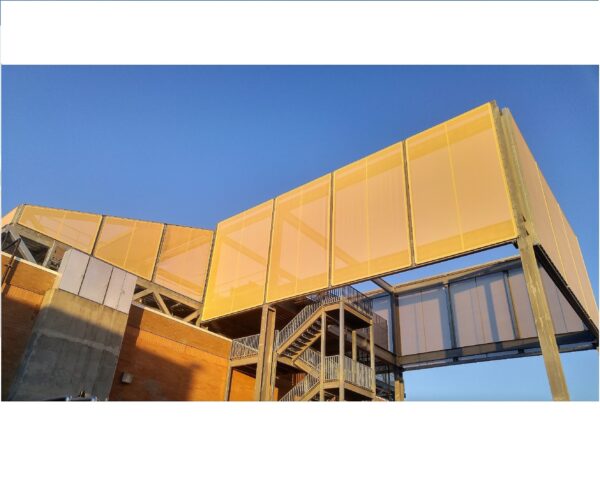

This PVC mesh fabric cladding system was designed to replace the existing façade at Sainsbury’s in Crayford which had reached the end of its life. The refurbished fabric panel design gives greater protection from the elements and busy industrial environment extending the lifespan of the building, as well as an updated look for this busy retail store.

The structures consists of 1000sqm PVC mesh panels held by aluminium extrusion and fitted into an existing timber frame. The tensioning detail is covered by an attractive aluminium flashing.

The panels also serve as additional weather protection for customers where they join the walkway canopy we installed previously to the store exterior.

In September 2010 the Sainsbury’s store, Crayford reopened after an extensive re-fit, increasing in size from 30,000sq ft to 100,000 sq ft to become the largest Sainsbury’s store in the UK. And to impress further, all the cooling, heating and hot water are provided by geothermal energy gathered 200 metres below ground. Consequently the new larger store has the same carbon footprint as the original, much smaller store. However, one problem remained; how to create a suitable fabric facade befitting a flagship store of such grand scale and landmark innovation?

The solution, of course, is tensile fabric. Sainsbury’s have been pioneers of tensile fabric use for many years, recognising the practical and aesthetic benefits of an eye catching structure. In this instance a covered walkway measuring a total of 126 metres in length runs across the front of the building, flanking the central floor-to-ceiling glass entrance. Vertical PTFE mesh panels measuring 7 metres high create a clean, understated frontage that allows a greater transmittance of light than solid fabric and excellent circulation of air, in turn helping to lower heat gain. The roof of the walkway is a flat, inclined PVC membrane that allows water to run off towards the rear of the walkway into a gutter system. All the individual fabric panels are fitted to steel picture frames which are in turn fitted to glulam columns and beams, allowing for efficient installation of the fabric.

Working as a sub contractor to Aura Custom Ltd, Base were responsible for the manufacture and installation of the tensile fabric membranes. To ensure that the fabric panels were a good fit, the steel frame was surveyed after it was fully installed in order to make minor adjustments to the patterns where necessary.

The barrel vault fabric panels are slid into an aluminium luff track extrusion on three sides. The panels are tensioned out by means of threaded studs on the membrane plates, the final tensioning being achieved with the adjustable cable in the pocket on the front edge. Base Structures offer various services to other partners in the tensile fabric industry.

We were asked to provide three different types of canopies for this riverside project which is on the site of the former infamous Skindles Hotel. An adapted canopy from our ‘off the peg’ range was used to provide a dramatic entrance feature for the new chic Thameside brasserie.

The river facing rear terrace required a distinctive bespoke solution to protect the diners come rain or shine. This was achieved with a triple conic with internal rainwater drainage and a structural gutter for maintenance access.

Finally to complete the look at this enviable waterfront spot we supplied the lower terrace with a 9.9m long folding arm motorised awning complete with printed Roux logos.

The client required a striking tensile fabric covered walkway as part of their new residential sales office created from recycled containers.

We designed, fabricated and installed the PVC fabric canopy, associated steel structure, cables and fittings.

This tensile fabric structure creates a futuristic and welcoming ambiance to the offices, that all parties were very pleased with.

The client required a grandstand tensile fabric canopy and wall system to cover to the seating area, however the Royal Dublin Society stadium frequently hosts concerts and events for which the central section of the existing grandstand is removed to allow a stage to be erected in its place. This meant the fabric canopy would also require a removable central section to follow suit.

Fabric structures are very versatile and in this case proved a good solution for the removable section, whilst also being an attractive way to provide the much needed functional seating cover. We designed and fabricated the fabric roof canopy, side cheeks and rear walls.

The project was completed on time and on budget and fabric canopy is credit to all involved.

Our brief was to design and install a fabric ceiling system within the museum which would also act as a diffuser for the concealed lighting. It creates a dramatic effect to the interior space and the fabric membrane provides a suitable backdrop for the hanging aircraft display.

We designed, engineered, manufactured and installed the fabric ceiling system for the museum. This includes the fabric, extrusion and fittings. We also fitted a fabric soffit to the building exterior.

The project went very well and has been featured in the architectural press. The new museum space and displays have proved very popular with the public.

To help counteract the searing 40°C plus heat, Qatar has launched a cooled Fan Zone to enable football fans to watch the Brazil 2014 World Cup in relative comfort. A temperature difference inside the structure of around 13°C is maintained by using of a range of technology including ventilation units, high level jet nozzles to restrict prevailing winds and air-controlled modifiable dampers. Importantly the Fan Zone is being used by engineers as a trial to perfect the cooling technology that will be required when Qatar plans to host the 2022 World Cup. It houses the biggest LED television in Qatar and a variety of interactive football themed attractions.

Base Structures manufactured 22 triangular tensile fabric sails, arranged in 11 pairs that overlap each other to encircle the Fan Zone, lending a dynamic and eye catching facade to the otherwise unassuming building. Manufactured using nearly 150m2 of white PVC fabric per pair of sails, the natural translucency of the material is exploited with banks of lighting used to bathe the sails from behind with a wash of cool blue colour and projected patterns. A ‘cool’ project in every sense of the word.

Priory Community School is an Academy Trust located in Weston-Super-Mare who approached us with a brief intended to make better use of their exterior space. Whilst the school has a generous outdoor area for the students, they lacked an external facility that provided effective shelter from the elements. The scorching coastal sun was as much a concern as the wet weather that can often drive up the Bristol Channel – what they really needed was a tensile fabric canopy.

When we visited the school to discuss the brief and present the multitude of possible options, it quickly became apparent this wasn’t your average client meeting. In attendance with the Principal were the students themselves to help inform the choice of structure for their school. Together they brought an interesting perspective to the process, in particular specifying that the completed structure must not obscure the view of the surrounding school grounds with walls or visual barriers.

To best fit their brief and the school site, we adapted a single bay, pre-designed Malvern canopy into an extended three bay walkway style canopy measuring 7 metres wide and 21 metres long. Not only do our pre-designed canopies bring cost efficiencies, they can also be easily adapted to suit a particular brief.

Finished with a specified colour scheme of cream PVC fabric and grey coated steelwork with canopy up-lighting embedded in the floor, the school has a fantastic addition to the playground that we hope the pupils will feel proud of. Here’s hoping we score an A+!

The client required a replacement for the ageing existing fabric roof market cover at Portobello Road Market. Our brief was to provide a new canopy, similar to the existing one but incorporating the latest detailing and tensile fabric technology. This structure provides shelter for the shoppers and market traders as well as encouraging the shoppers to the area. We designed, manufactured and installed the new fabric canopy including rigging cables and fittings.

We are very proud to have been involved in this prestigious project. It was a good job to work on and the clean new canopy has dramatically improved the ambience of the market. Our clients Westway Development Trust were very pleased with the new canopy and the market traders and shoppers continue to be able to trade out of the rain!