Abbey Wood Retail Park in North Bristol commenced a £10 million revamp in March 2013, creating in excess of 100,000 square foot of retail space in an area located near offices, a University campus and a soon-to-be built football stadium for Bristol Rovers. With such an exciting mix of shoppers and future regeneration planned in the area, it was a key criteria for the new development to reflect the vibrancy and sophisticated expectations of local shoppers, which is where the idea for a feature canopy was born.

Adapted from one of our pre-designed canopy structures, the Malvern 4P 700, this example dwarfs the original at nearly twice the size. Measuring 12m across, the fabric canopy provides plenty of shelter from both sun and rain, covering a large seating area for weary shoppers. Specified with grit polished stainless steel masts and a PTFE canopy, this structure will retain it’s good looks for many, many years to come. A colour changing LED lighting system embedded in the floor also transforms the structure after dark, bathing the canopy in a changing spectrum of colours visible to commuters on surrounding roads and railway lines.

Standing proud with a large sweeping sail, the fabric canopy greets shoppers like an old friend with outstretched arms as they enter the retail park.

London’s Camden Market’s carnival atmosphere famously attracts people from all walks of life and is popular with Goths and Punks who live and work alongside the traditional antiques and clothing traders. Due to increased visitor numbers, this borough of London has recently attracted substantial development funding enabling a gradual and sympathetic facelift to take place. How apt that this beautifully crafted walkway canopy should adorn a building that sits at the heart of London’s bohemian arts and crafts district.

We decided to use Tenara material which is 100% PTFE and is manufactured to very high quality standards. Accordingly, it benefits from high levels of translucency such that the light striking the smooth curves of the canopy is evenly diffused, lifting the whole structure and making it appear to fluoresce. The twisted, eccentric steel framework which carries the fabric is constructed of many irregular curves making the geometry of each bay completely unique. Needless to say the patterning of the fabric was a monumental task, and yet it fits so well.

Set as it is against a backdrop of muted coloured glass curtain walling set in steel grey frames, this installation promotes the fabric so that it appears to shine like a pearl unearthed in this most unlikely of habitats. The completed project is a true testament to the combination of visionary artist and engineer.

Jan Blake asked us to manufacture tensile fabric sculptures that she had designed for her client Centrica Head Offices in Windsor, which she could then paint artwork directly onto. The structures were to provide a dynamic use of interior space and to be unique features to impress visitors at the offices.

We manufactured the three sculptures which included the silk fabric, patterning and attaching the fabric to the frames. We were also on site to assist with the installation. This type of material is very delicate and therefore we took extraordinary care to ensure manufacturing went smoothly.

The finished objects work very well in their new environment. Jan Blake was extremely pleased with the forms produced and she painted them in our factory. Centrica were also very pleased with their re-vamped offices.

The Cheshire Oaks designer outlet centre in Elsmere Port, wanted a tensile fabric canopy to provide a venue for outdoor events. This would also add to the ambiance and improves the shopping experience as well as acting as a meeting point for shoppers.

We adapted and repeated our Chiltern 3P 600 canopy from our pre-designed range, to extend the coverage and create a canopy to suit the clients needs. We also manufactured and installed the fabric courtyard canopy, its supporting steel structure, foundations, paving and lighting.

This was a turnkey project which satisfied the clients needs whilst causing them minimum disruption.

Chessington World of Adventures Zoo required assistance in re-developing their existing Squirrel Monkey enclosure with a new netted roof.

We designed, supplied and installed a bespoke solution that involved fitting PE mesh netting to the exiting support timber frame and monkey housing.

The new net roof has dramatically increased the living space available to the squirrel monkeys by allowing them to explore up and out of their existing enclosure whilst still being housed safely.

The spectacular Cutty Sark deserves to welcome its visitors in a spectacular venue. Therefore, this multi-cone tensile fabric structure had to be one of the most unique architectural fabric creations in the country. By day, its peaks resemble crisp meringue; by dusk, the detail in the beautifully lit cones truly comes alive.

The seventeen tensile hexagonal cones have a unique relationship with their timber grid below. In short, one cannot survive without the other. The fabric locks the grid in place, providing the awesome strength needed to hold this beautiful beast in place. A true example of collaborative working processes, from conception to completion, the engineering, timber and fabric all had to work in perfect harmony.

Conceived by innovative architects Youmeheshe, the fabric structure strikes an arresting mark on the landscape. It is not just its visual form that breaks new ground.

Having approached Base structures about a similar scheme at the outset of the works, Dublin Airport came back to us in October 2008 with a proposal to close off the southern elevation of the building with two and a half thousand square metres of weatherproof fabric.

After receiving the brief Base set about designing, manufacturing and installing this completely bespoke and fully engineered solution in less then seven weeks, with the site install time barely exceeding two of these.

This speed of service, combined with the durability, weatherproofing and reliability of the installed scheme enabled the construction team to recover time on the €609m project and made a significant contribution towards completion on the May 2010 deadline.

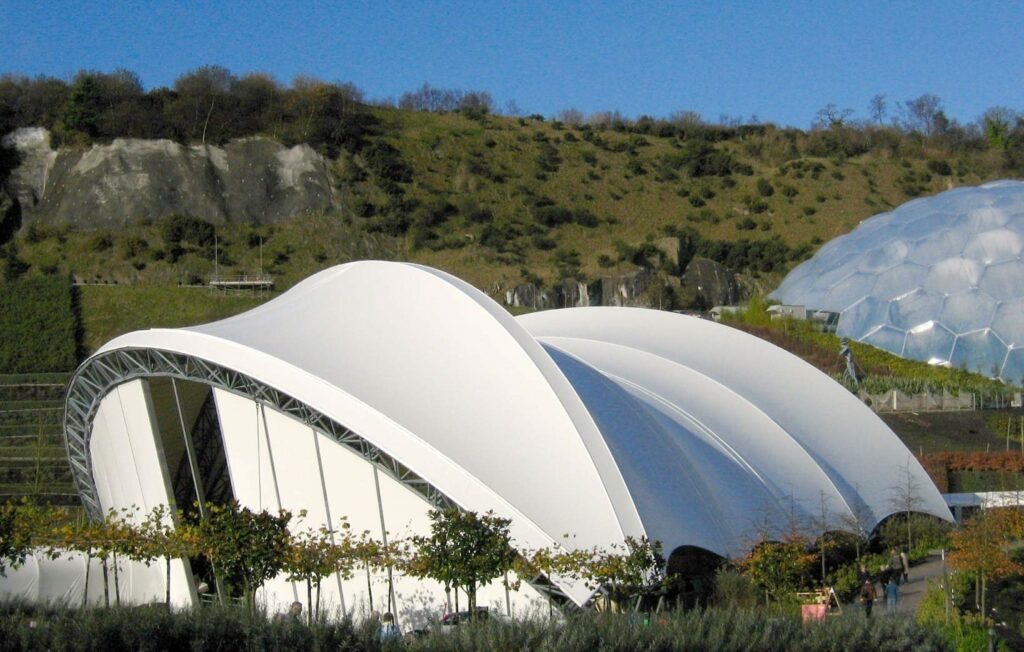

Our brief was to install a tensile fabric roof structure to the new ice rink and events arena at the Eden Project in time for the National Lottery’s 10th Anniversary celebration 2004.

Our scope of works was to pattern, manufacture and install the fabric membrane over the steel frame supplied by ESS. This was a large project with an immovable deadline and it took a huge team effort to get it done on time. It was a very rewarding job to be involved in and it looks great.

The fabric structure serves not only as a roof but as a new feature attraction at the site. Choosing a fabric building has allowed the client to go for a unique, contemporary and impacting design. It also compliments the existing Eden Project structure and ESS were delighted with our quick and professional installation.

Base Structures were extremely proud to be working together with Caddick Construction on the plans to transform the Emerald Headingley Cricket Ground.

Much has changed since the crowds poured in to watch the first Test at this truly iconic and world-famous sporting venue in 1899. The addition of the new 4,300 seater main stand will make Headingley one of the finest cricket venues in the world.

Base were tasked with the design, manufacture and install of the fabric roof and bespoke gutter system on the new Emerald main stand, the centrepiece of the Headingley redevelopment project.

The cantilever stadium roof comprises of ten bays, each of which is covered by Ferrari’s high performance membrane, TX30-II, which benefits from a 30 year lifespan.

Fabric installations can be a tricky game at times due to inclement weather, especially at height and when conducted solely by Rope Access Technicians. However, our installation was unhampered and benefitted by the long, hot and settled summer weather. It was a touch too warm at times up there…due to the fabric glare, temperatures peaked at 48°C!

Every year a covered green space in which to relax is generated within London’s famous Square Mile as a place where executives and their clients can go to view dinner time theatrical and musical events. Base Structures were commissioned by the client to replace the existing tensile fabric covers in Exchange Square, which were starting to look tired.

In order to reproduce the existing covers Base Structures design department had to survey the steel and cable net structure from which they could generate the ‘form’ of the new structures.

As you can see from the pictures, this was achieved very successfully and the new fabric structure once again looks fit for purpose.