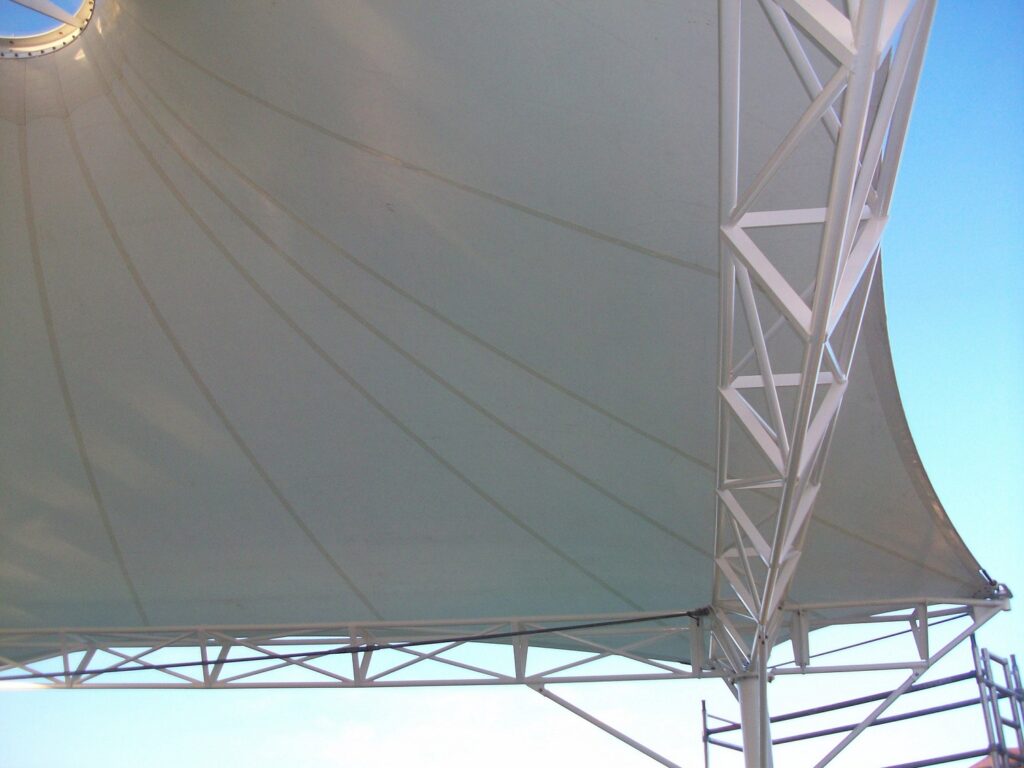

This tensile fabric cladding system is designed to cover the existing space frame roof to the Park West Railway Station. Having not long completed an identical tensile structure at nearby Adamstown Railway station, our clients Mero and Irish Rail were very pleased with the success of that structure and happy for this second fabric clad roof to go ahead.

Using fabric as cladding in this way allows far more natural light into the building than more traditional alternatives and creates a very pleasant station environment.

Our brief was to build a covered walkway canopy as a feature for the new village centre building. The fabric structure provides sheltered access and serves as a method of improving the image of the centre to visitors. We designed, manufactured and installed the fabric walkway canopy including the supporting steel structure, rigging cables and fittings. We also installed the perforated stainless steel balustrade and hardwood walkway and handrail.

This project was fairly complex with the combination of the balustrade and relied on good preparation. The installation went very well and in on time.

The structure looks good and has improved the centre. All parties are pleased with the results.

Following a fire at the Bus Station in which large areas of the existing tensile roof structure was damaged beyond repair, Base Structures were commissioned to remove the fire damaged areas of fabric, survey the existing steel and assess for structural damage, and then to replace all damaged fabric elements with new and make good the finished tensile structure.

The existing roof is made up of a double skin PTFE multi barrel-vaulted structure contained within a large, essentially triangular, outer ring beam. All fabric elements were fixed to the steel structure via luff track or clamp plates.

An aluminium facade contains the guttering and gives a nice finished appearance to the entire perimeter.

Sitting at the heart of Malinslee, Telford, The Old Park Centre is at the heart of the community. A regeneration project in 2008 aimed to act as a catalyst to lift a deprived area of Telford into a blossoming community hub. Part of this project resulted in the amalgamation of two existing schools into the newly formed Old Park Primary School. This new school had been carefully designed by BBLB Architects to accomodate 450 pupils in as stimulating an environment as possible. The external areas of the school were of great importance to the overall design and redevelopment initiative and this attractive membrane canopy plays a key role.

A multi-conic walkway to provide protection from the elements and allow year round use of the outside environment by the children. The perspex domes at the top of each cone allow increased light levels under the canopy in dull weather whilst the membrane shelters the pupils from both sun and rain.

The entire quadruple cone was manufactured and lifted into place in one piece and will enable enjoyable outdoor playtimes for a long time to come!

As a part of Tower Hamlets biggest ever spend on school improvements, the local council has partnered with the construction company Bouygues UK, to deliver £230m of refurbishment as a part of the Building Schools for the Future (BSF) programme across their borough.

Base Structures were given the opportunity to tender for this project following previous successful collaborations with the Director of one of the senior companies already involved. The early brief from the project engineers identified that the canopy could not impose additional loads onto the surrounding parts of the building and so the entire structure is supported solely by the four corner columns which are bolted directly on top of the existing building’s structural steel skeleton.

For this reason and due to the position of the canopy towards the top of the building, extensive lightning protection had to be added across all of the joints in the steel framework so that in the event of a strike, the massive electrical charge would pass through the building and be harmlessly dispatched through existing steel structure to earth.

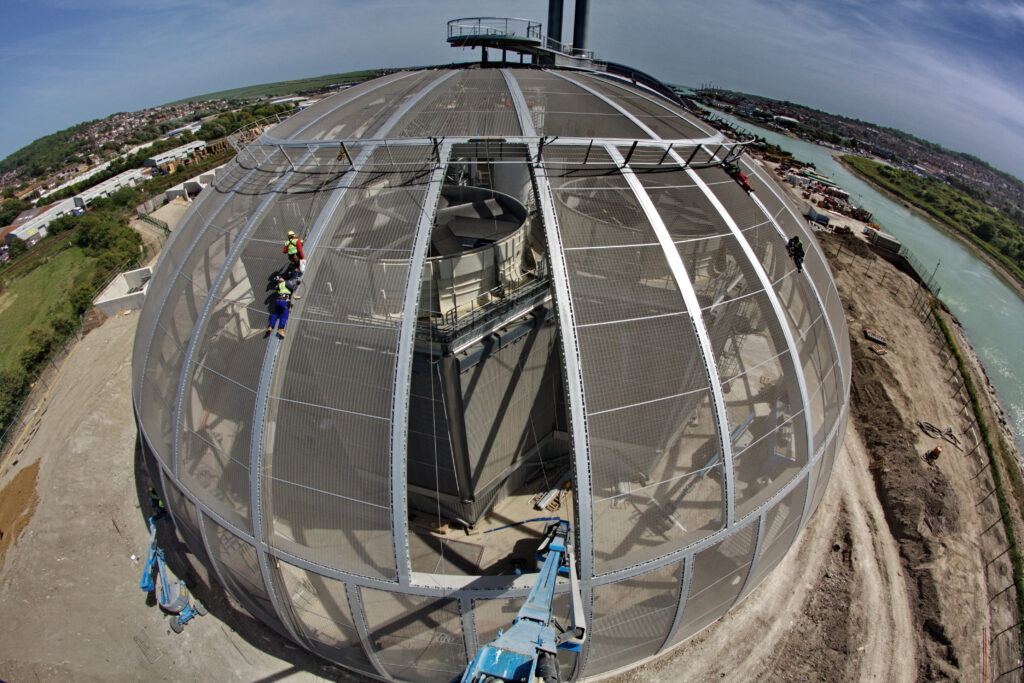

Base Structures were asked to tender for the fitting of a screen to minimize and soften the industrial visual impact of the cooling section built at the rounded northern end of the new £140 million Energy Recovery Facility (ERF). When operational this new ERF will take receipt of some 210,000 tonnes of municipal solid waste each year, to be treated in two boilers. The challenge to Base Structures was to install a suitable screening for the air-cooled condenser area: a 54 m diameter half dome on the northern end of the Newhaven ERF which needed to obfuscate the harsh detail of the externally mounted cooling equipment and yet would allow the necessary volume of air through it.

Delivering a structural solution required us to develop a fully engineered aluminium fabric clamping detail that would complement the inherent flexibility of the fabric thereby ensuring that the daily stresses and strains imposed on these very large wind catching sails would dissipate uniformly into the enclosing skeletal steel frame.

“We hit upon the idea of a ‘wavy’ clamping system,” says Base Structures’ Head of Projects, Mark Smith, “using an aluminium extrusion which allowed us to pass the load evenly through the steel, rather than through the PVC. We made a series of different prototypes until we evolved a fully engineered design that achieved the loads necessary.”

The architect identified a 50% open mesh fabric as delivering on these functional criteria. To enable this relatively light weight architectural mesh material to perform structurally it contains galvanised steel threads which are woven through it to a regular pattern.

Two different clamps were developed: an ‘intermediate’ design to hold the sections of fabric together, and a ‘perimeter’ design, used to clamp the joined sections to the supporting steel structure. The only modification necessary was to pre-stress the mesh before it was clamped in.

Installation of the mesh above the heavy process equipment took around six weeks for a team of six on the ground fitting sections together and 14 riggers, clamping and bolting the sections into place. Having refined this techique, Base Structures is confident it will significantly reduce this build time for future projects.

Like a vision taken straight from the set of Blade Runner, East Sussex’s new Energy Recovery Facility perches in the estuary of the River Ouse reclaiming the energy stored within our waste which would otherwise end up as landfill.

“Base Structures found a technical solution on the basis of their knowledge, creativity and problem solving attitude. They transferred successfully the information from design study onto the final construction.”

Andreas Clausen, HOCHTIEF Construction Manager

Base were asked to design, manufacture and install the branch frame canopy including the supporting steel structure, fabric membrane and associated fittings.

This fabric canopy forms part of the refurbished entrance to the Multi Storey Car Park at Gatwick Airport. It not only provides protection for car park patrons when using the ticket machines but also serves as an attractive architectural feature to enhance the surroundings.

We designed, manufactured and installed a series of high level tensile fabric barrel vault canopies over the existing walkways surrounding the building.

With the addition of two dynamic, four cornered hypar sails over the entrance, an otherwise unremarkable new building becomes an elegantly land marked feature on the cityscape.

We were commissioned to design, fabricate and install a fabric covered walkway structure as part of the courtyard landscape at the Medicentre.

The tensile structure, which consists of five fabric sails supporting steel structure and integral lighting, provides shelter to patients traversing between two buildings as well as being an attractive addition to the courtyard. When lit up in the evening, the structure creates a very dramatic effect which the client is very pleased with.

The Nursery Pavilion at Lords Cricket Ground was constructed in 1999 to provide a venue for match day hospitality. Overlooking the Nursery Ground which is used by players to warm up before a match, the pavilion was in need of refurbishment. The brief was for a direct replacement following the exact same roof line, in order to meet planning constraints.

Thanks to innovations in tensile fabric, Base was able to suggest replacing the original 18 piece fabric structure with a single piece design, eliminating the need for the original unsightly metal clamps and speeding up the manufacturing and installation process.

The resulting canopy is a five cone tensile structure using 1900m2 of architectural PVC fabric, requiring an unusual five crane lift for installation. Base’s role included removal of the old pavilion fabric canopy, the detail design, manufacture and the installation of the new replacement. We also oversaw the refurbishment of structural steel and a flat roof structure.