The ‘Lilas’ leaf and petal design on the fabric was by the Pitzker-Prize winning architect, Zaha Hadid. It is 5.5 meters in height and is formed by three identical tensile fabric parasols arranged around a central point.

The clients brief was to pattern, manufacture and install this unique tensile fabric structure as a focal point for the Serpentine Gallery’s ‘Summer Party’.

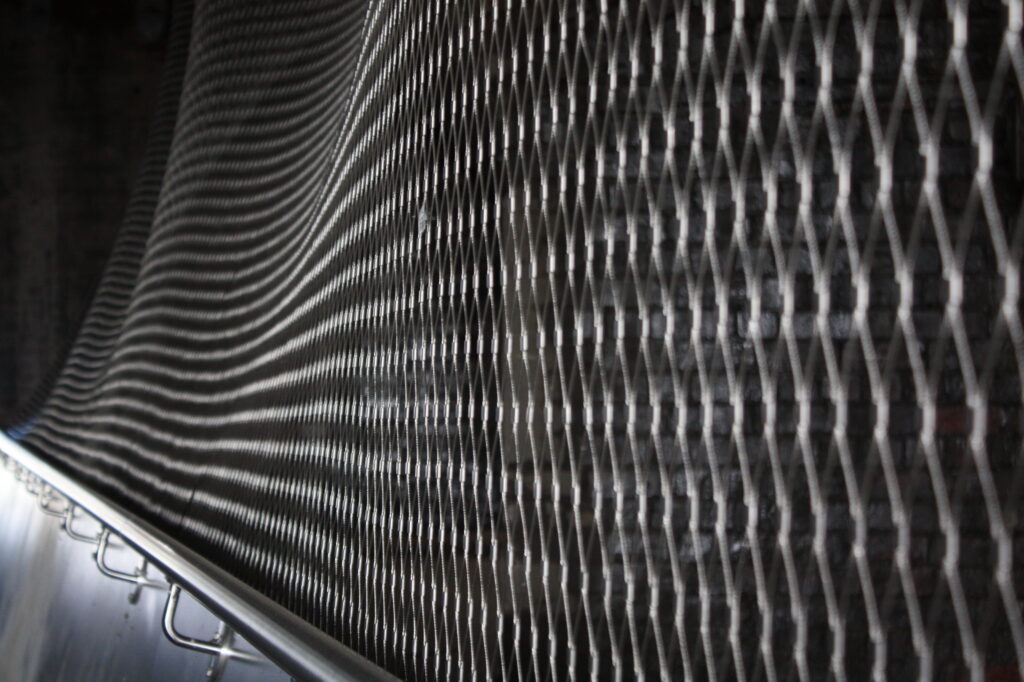

The Highways Agency anti-corrosion programme for the Severn River Suspension Bridge requires the sealing of the cables with Hypalon fabric wrapping. Initially we supplied rope access labour to assist with the wrapping work but whilst on site we soon realised that the process could be much improved with the use of an inflatable welding blanket.

Using technologies developed through out core business of manufacturing Tensile Fabric Structures, we designed, manufactured and supplied a solution incorporating an air cushion that when pressurised, formed itself onto the surface of the main cable whatever the size or shape. This system successfully speeds up the de-humidification process and improves the quality of weld and has been widely adpopted within the bridge cable wrapping industry.

We completed the first phase of these works in 2007 but this is an ongoing project with further phases of work and many more bridges and cables to go!

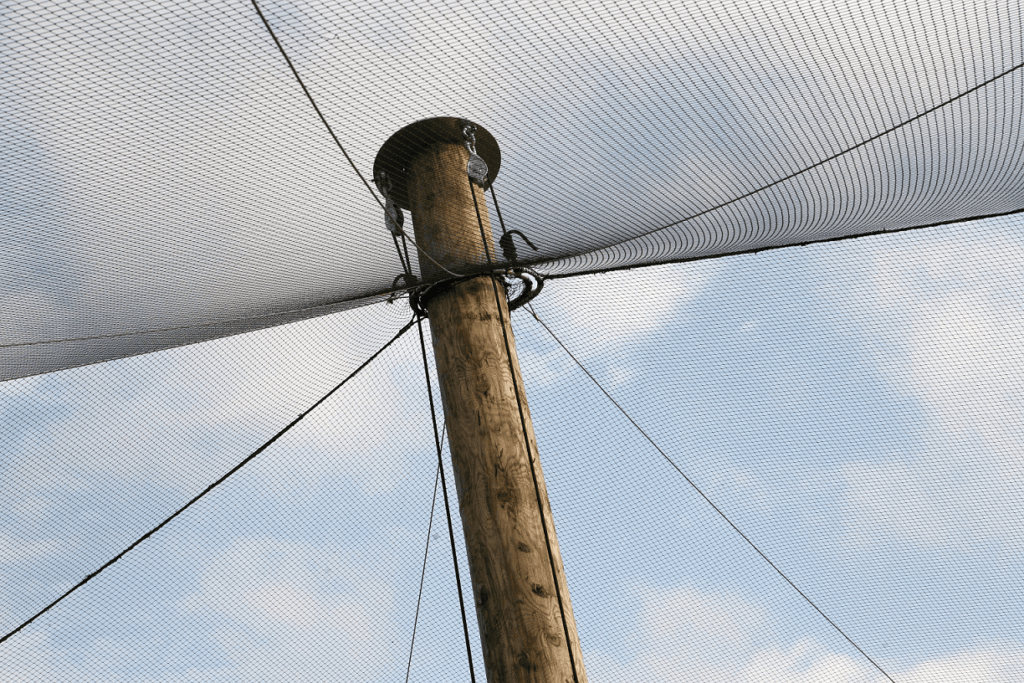

The Wildfowl and Wetlands Trust approached Base Structures with a specific problem for their proposed new exhibit housing Redshanks and Avocets. They needed a world class enclosure that did not feel enclosed, had an exceptionally low environmental impact and was as affordable as possible to construct, install and maintain. A fundamental requirement was also for the fabric of the structure to be wader bird friendly; these species are very fragile and if spooked can easily damage themselves on solid obstructions.

Paul Pattison, Development Projects Officer, Slimbridge WWT

Andy Traynor, Project Manager, Base Structures

To provide as natural an environment as possible, the enclosure uses tough 25x25mm knotted polyethelene, a surprisingly unobtrusive material that is not visually dominating. From inside the enclosure the netted walls appear to be almost nonexistent against the surrounding landscape, providing an incredibly natural environment for the birds. This is enhanced by the supporting timber posts and netting surfaces being installed at various angles, creating a natural effect with no perpendicular lines, helping to minimise the man-made appearance of the enclosure. To offer protection to the delicate wading birds the supporting timber posts around the edge of the enclosure are all placed outside the netting, preventing possible injuries if the birds are scared into flight.

The biggest environmental savings were achieved by using construction techniques that did not require the use of any concrete. As such, the supporting structure was installed using alternative foundation techniques that did not literally cost the earth. Fully engineered timber posts hold up the entire net structure, providing the necessary support with a natural, renewable material that is no more intrusive within the enclosure than a few slender trees.

A key requirement from the Trust was to ensure that the structure would be as economical as possible to maintain in the future. As a critical design requirement from the very beginning of the project, we managed to engineer a solution into the structure that alleviated the need for carrying out inspection or repair at any great height. We achieved this with a very simple system; the netting is attached to metal rings that are slightly larger in diameter than the structural timber posts, these rings are hoisted up and down the posts by a system of ropes and pulleys from ground level – being simply tied off to hold the netting in final position. Thus the whole netting structure can be easily and quickly lowered down the supporting timbers for any work to be carried out at ground level, ensuring significant costs for the lifetime of the structure.

We worked closely with the Trust to supply this enclosure in kit form, allowing them to use their own equipment and expertise to install the structure with minimal supervision from ourselves. Our comprehensive survey provided the exact locations and angles for the timber posts, after these were installed by the Trust we fitted the cabling, in turn enabling the Trust to install the netting themselves and complete the installation. Once installation was successfully completed the team at the Trust had also gained the necessary experience to undertake any future maintenance themselves.

The Trust are thrilled with their new visitor attraction, the cost savings achieved in construction and the knowledge that the enclosure will continue to perform in the future for minimal outlay. The birds have settled in superbly and exhibit their natural behaviour, presenting visitors with a privileged experience; to see the birds acting naturally at close quarters without feeling you are confined in a restricted space. The Trust have commented that they hope the birds may eventually breed, a sure sign of success! This would then become an even bigger attraction for visitors, helping to develop visitor empathy and fondness for the birds which is beneficial to the broader WWT conservation efforts.

Our client asked us to design, fabricate and install a banner system that would be able to withstand the extreme weather systems at the top of this 150m high tower, adjacent to the Irish sea. The banners are supported on an aluminium system fixed back to the structure via a steel sub frame.

We designed, engineered and installed this system then manufactured and installed the fabric banners. This solution has worked well. Working at such a height required top notch rope access operatives, who did a great job. Albeit a scary thought for most of us, they thoroughly enjoyed it.

The pupils of St Michaels school in Kings Lynn look forward to their playtimes more than most. It is not because their lessons are boring however – in 2010 the school completed a playground remodelling program complete with a new colourful play surface, a tree planting scheme and a contemporary tensile fabric structure, which we were asked to provide.

No tie-rods are needed on the steelwork for this structure, meaning there are no trip hazards for the children to injure themselves on whilst they recklessly chase each other around. Whilst the structure may be part of our pre-designed range the client could specify the exact RAL colour for the steelwork, in this instance they chose a rich, deep blue.

Choosing one of our pre-designed structures to maximise their budget, the Mendip 6P 500 presents a real focal point in the playground environment, the expressive curved steel masts creating a sculptural tensile fabric canopy that provides shelter from the sun and rain.

Our brief was to install temporary wraps to the columns at the entrance of Tate Britain, as a special feature linking in with the David Batchelor artwork exhibition taking place at the time. The wraps acted not only as an advertisment for the exhibition but were a vibrant and imaginative use of the existing buildings architecture.

The project was more complicated than it looked as each natural stone column is unique and therefore each one had to be individually surveyed by our climbers before patterning the fabric to suit. We manufactured the wraps from fabric printed to the colours specified by the artist and installed them at night, once again using ropes access techniques. The Tate Britain Museum were extremely pleased with the result of the finished product and the high quality.

Designed exclusively for couples, The Rendezvous Hotel is an idyllic and intimate Caribbean hideaway, set on a beautiful two-mile stretch of white sandy beach and surrounded by seven acres of tropical gardens. To cover an outdoor seating area where couples and honeymooners enjoy the finest cuisine right at the water’s edge, an open tensile fabric canopy was needed to provide both solar shade and the occasional rain protection.

Based on one of our previous projects at Priory School, our pre-designed Malvern canopy was modified for this restaurant to ensure its high points were in the middle of the structure whilst its low points were on the edge. This was for practical reasons to ensure that staff members could easily access the seating area without the canopy getting in the way whilst serving customers. Also, due to the surrounding marine environment, we needed to use a very high specification of stainless steel to avoid any rusting. Finally, due to the risk of occasional hurricanes and high wind speeds, the restaurant needed the ability to dismount the fabric when necessary.

We may be biased, but the Toes in the Sand restaurant would definitely make it onto our bucket list. The addition of a tensile fabric canopy creates a more modern and stylish look to the restaurant whilst providing an intimate atmosphere for diners… who knew tensile fabric could be so romantic!

As part of their recent extensive renovations, Twycross Zoo wished to create a new focal point to the zoos entrance. To this end they commissioned a new visitor centre comprising a café, bar, gift shop and two new exhibits, one displaying their world renowned collection of wading birds and the other a flagship enclosure displaying the brand new snow leopard collection. Base were involved in the design and installation of this snow leopard enclosure.

The snow leopard enclosure faces onto the new visitor centre and is formed from galvanized steel perimeter posts and tie rods, supported by stainless steel cables and netting, keeping the people of Leicestershire safe from the snow leopards, and vice versa.

The snow leopards of Twycross zoo settled into their enclosure quickly and comfortably while visitors can enjoy the beautiful animals safely.

For our clients who run and manage zoos, animal welfare is their top priority. Most zoos exist as an opportunity not just for the public…

Following the success of the London 2012 Games, the Olympic Park in Stratford underwent another transformation to turn it into what is now known as Queen Elizabeth Olympic Park, fully reopening to the public in April 2014. Base were tasked with transforming an existing underpass in the south of the park (identified with the snappy name of U06) that was used as a pedestrian link to Pudding Mill Lane station. Consisting of a series of brick arches measuring 60 metres long, the underpass traverses directly underneath the Great Eastern main railway line.

Base fabricated and installed a cablenet supported lighting system consisting of 61 waterproof fluorescent luminaires suspended from a tensioned steel wire catenary with electro-polished fittings. Running the length of the underpass the cablenet is fixed to the existing brick structure of the underpass with cintec anchors. Elements from an existing cablenet structure on the Park that had been dismantled were reused to maximise value for money and sustainability for the project.

An additional infill webnet closure panel was also set up along a section of the underpass. Running from the floor to fixing points on the vertical wall of the underpass, the flexibility of the mesh was utilised to create undulations as it attached to high and low points on the wall.

A wide range of shapes and fabrics for the internal structures were employed ranging from internally lit tensile lycra cones to multi-coloured silk flags for a Himalayan inspired feature.

Tapered prisms were suspended above the check out desks wrapped in a leaf patterned fabric. A golden brown silk fabric was tensioned onto lightweight leaf shaped frames and was grouped on branches as well as being suspended in an array of twenty above a main aisle. Finally in an external courtyard triangular mesh fabric sails were tensioned between stripped bark timber poles set in concrete foundations to act as a sun shade.

Van Hage Garden Park is an excellent example of the range of fabrics and forms that can be used to good effect in one project.

With a maximum of 24 guests allowed at any one time and spacious bedrooms with en-suite bathrooms, this is the ultimate safari experience.