The sports hall situated in Fynshav, Denmark were after a mesh vaulted interior ceiling, so partnering up with BK Teknik – our preferred partner for Danish construction projects, we got started with the single membrane measuring approximately 20m x 42m.

The tensile fabric is supported by a series of suspended headrings in the centre of the roof structure which is then pulled down and tensioned to a series of timber glulam beams via a traditional membrane plate and cable perimeter edge.

The purpose of this membrane is not only to improve the appearance of the internal space but also to diffuse the natural light which enters the building via the extensive sky-lighting. Both certainly are the case for this project!

This new restaurant in the high profile area of Camden required a retractable roof system for open air dining in the summer months. The tensile fabric membranes needed to allow natural light into the restaurant when the roof is closed, enhancing the interior space as well as being a dynamic feature.

We designed, manufactured and installed the motorised retractable roof system and the fabric membrane.

Home to Dim sum, sushi and cocktails, the roof system perfectly compliments the elaborate Indian-chic setting with wood carvings and an open kitchen.

A new generation of temporary mobile structures was to be developed for the festival and entertainment sector, starting life at Glastonbury Festival 2007 as the Glade Stage.

We made the fabric roof canopy in PVC and the steel in a light weight lattice structure that has the ability to cope with different ground conditions, depending on the location of the event or festival.

A practical and visually appealing solution to temporary event stages within the entertainment industry.

The client, Glaxo Smith Kline, were obliged to provide the screens to the side of their building in Ware, Hertfordshire, in order to obscure the large M&E ductwork behind. The screens will eventually support Wisteria climbing plants, which will grow and increase in weight over the years.

The GSK Living Screens project comprises three large steel frames approx 11m wide and 17m high to each of which are fitted five separate sections of cable mesh. The architectural mesh is supported by means of perimeter stainless steel cables which are in turn connected to the structure via fabricated stainless steel plates. The support system has a tension absorbing spring system. Wisteria climbing poles are fitted in front of the mesh. The purpose of the screens is to support vegetative growth which is in turn intended to conceal the ductwork behind.

In order that the growing climbing plants do not overstrain the netting and structure, the horizontal support cables incorporate stress relieving springs. The mesh fitted is a high quality Swiss made product renowned for its appearance and performance, precisely patterned to fit each application.

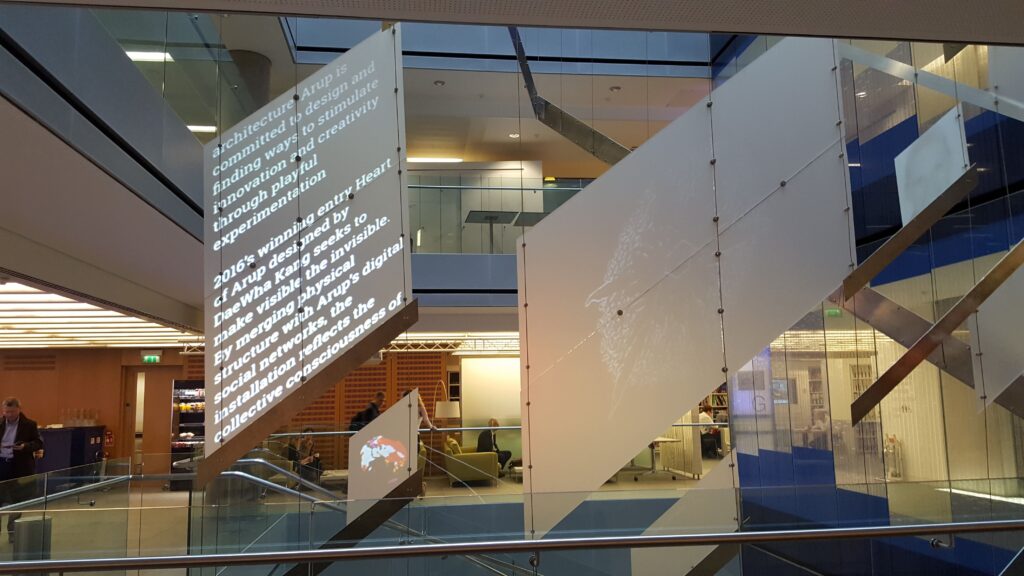

As one of the world’s largest engineering consultancy practices, Arup commissioned a futuristic design, merging the digital world into physical architecture. Following the No.8@Arup competition and DaeWah Kang Design’s winning entry, “Heart of Arup,” Base were approached to source, supply and install this innovative art installation.

Forging a relationship with the design team, Base was approached to source, supply and install the stainless steel cable system and aluminium stretchers for this exciting project. Our challenge was to develop a suitable design for the project that not only met the budget constraints, yet was also delivered to an extremely tight deadline for the installation – within one weekend! After successful completion, Arup is now able to experiment with the installation and we’re excited to see what this could mean for the future of media architecture.

The Heart of Arup is an interactive multimedia experience that now gracefully hangs within the atrium space at Arup’s global headquarters in London. Social media feeds from the company’s network, Yammer, and is visible within the six storey office. The art installation can be seen from many different points within the building, encouraging a natural form of communication from both public and working spaces.

Every world class cargo centre needs a world class dining area. The Cairngorm P100 structure needed to brighten up the site and provide shelter and shade for dining as well as complimenting the centre with an architectural glow.

Clothed in PTFE fabric, supported by stainless steel tubular tripods in all four corners and with a timber seating plinth mounted on the central mast, this structure truly is the benchmark against which all other standards should be measured.

In addition to the improved material specification, the design also called for a raised water diverter to the entire perimeter of the cone and therefore the corner plates to match have a built-in means of water catchment and disposal. The client particularly requested this enhanced level of specification for their new structure and amongst the high specification features is an extended warranty giving years of worry free use.

Our pre-designed canopy, Cairngorm 1P 1000 structure has had several outings in various guises over the last few years, but here it is shown in its most resplendent configuration to date.

Base Structures were commissioned to design, manufacture and install the departures tensile canopy scheme, one that would provide a truly stunning entrance to the new Terminal. As one of the first areas of Terminal 5 encountered by passengers, it was absolutely essential that we created a world class structure that made an exceptional first impression.

Andy Dearman, Architect, Pascall and Watson Architects

Paul Yates, Laing O’Rourke

Mark Randerson,SH Structures

Mark Smith, Project Manager, Base Structures

Duncan Baird, Site Supervisor, Base Structures

The project consisted of over 4000sqm of PTFE tensile fabric canopies that extended the whole length of the set down lanes at the terminal entrance. Additional canopies in the package included the car park entrance structures that reflected the main scheme. The eye-catching design utilises several series of a twisted hypar arrangement tensioned on an architectural steel frame complete with bespoke lighting. The sweeping undulations of fabric serving not only as shelter for passengers underneath but also as an outstanding architectural flourish to the terminal building.

A major contribution to Base Structures winning this tender was by partnering with a well respected steel fabricator from the beginning of the project. As the value of the steel exceeded the fabric content a more competitive price was achieved by having the steel fabricator as the lead contractor.

PTFE fabric was chosen instead of PVC to bring a number of benefits including increased translucency, higher strength, improved fire rating and a lower susceptibility to dirt. Being far more difficult to manufacture and install than PVC however required specialist skills to ensure the longevity of the structure was not compromised; poorly manufactured and installed PTFE will quickly fail. The accuracy and quality of the design, manufacture and installation are critical to the success of this material; when all these disciplines combine successfully PTFE has an exceptional life span as a tensile fabric.

As well as supply and fit of the fabric membrane Base were also responsible for installing the steelwork, fitting steel cladding to the lighting arms, installing bespoke lighting equipment and co-ordinating all works on site.

The installation was challenging and had to be completed in time for the grand opening of the terminal in March 2008. Our installation team were working on-site continuously for eighteen months, finally culminating in a seventeen man team for the last six months to ensure we could bring the project in on time.

The execution of the manufacture and installation reflected the high quality of the design and the expectations for the gateway to be the country’s new showcase terminal. The project was completed in plenty of time for the official opening of Terminal 5 by the Queen on 14th March 2008, finally opening to the public on 27th March 2008.

Although our client was sited in a campus of high architectural quality buildings there was a desire to introduce more informality in order to improve the working experience.

Alongside the introduction of a fabulous coffee cart, meeting pods and nature inspired wall graphics we were asked to provide an array of suspended leaves in their three storey atrium. To avoid a forest of suspension cables a stainless steel net was tensioned between columns at high level allowing each leaf to be on a single drop cable.

The leaves were UV ink jet printed with designs representing the changing colours of the seasons and were grouped in three arrays. The fabric selected was a PVC coated glass cloth mesh that has acoustic properties helping to keep noise levels down for those enjoying the newly invigorated space.

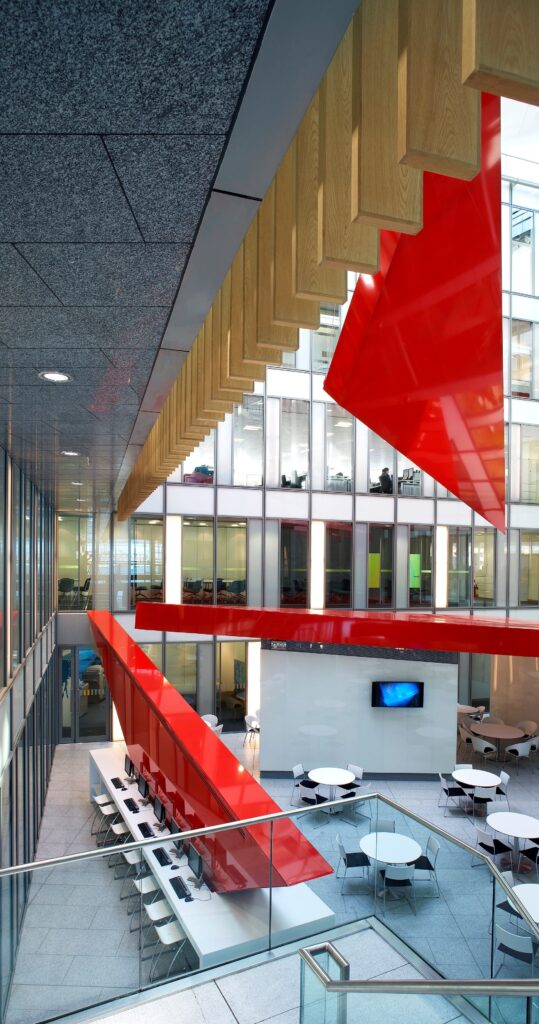

Architects LOM designed four large tensile fabric ‘shards’ forming a sculptural interpretation of the bank’s red logo for the atrium of their Dublin head office in Grand Canal Square.

In collaboration with Stretch Ceilings UK, Base coordinated the design of all the steel rafts as well as the fabrication and suspension of the largest hanging shard. The dramatic shapes which dominate the space were achieved with our unique combination of design, manufacture and rope access installation skills.

Our client approached us to assist them with a PVC roof structure over a Salt Barn that had reached the end of its lifespan.

We carried out a methodical removal of the old roof and gable panel and supplied and installed a new 1200m2 panel to the structure.

Given the size of the panel and the tricky crane lift this produced, the installation was particularly challenging during a windy autumn period. Further challenges presented were ensuring the salt was kept dry between the removal and replacement of the roof.

With a fixed deadline and delivery of several thousand tonnes of salt looming, we had to work swiftly and efficiently, using the old removed fabric to provide temporary protection.