We were briefed by Capita Symonds, the appointed representatives of Marylebone Cricket Club, to remove, redesign, manufacture and install the new tensile fabric roof over the Mound Stand, a monumental task that would not simply replace the old canopy but provide significant structural improvements through the use of more advanced materials and up-to-date design detailing. As such the replacement canopy would be expected to last significantly longer than the old one

Base Structures were able to provide the client with a methodology that ensured we would meet the tight deadlines, budgets and planning restrictions. This was made possible through the accurate surveying of the existing structure to ensure the replication of the iconic shape, and through the use of innovative access methods. It was essential that the project was undertaken and completed in one closed season so that our works did not interfere with or delay scheduled cricket matches.

The entire project was successfully completed ahead of schedule and below budget, no easy task considering the scale and complexity of the project. The replacement canopy not only restored the stand to its former glory but also improved the aesthetics and expected life span of the structure. Marylebone Cricket Club were extremely happy with the refurbishment and continue to use Base Structures for regular maintenance of this most iconic of structures.

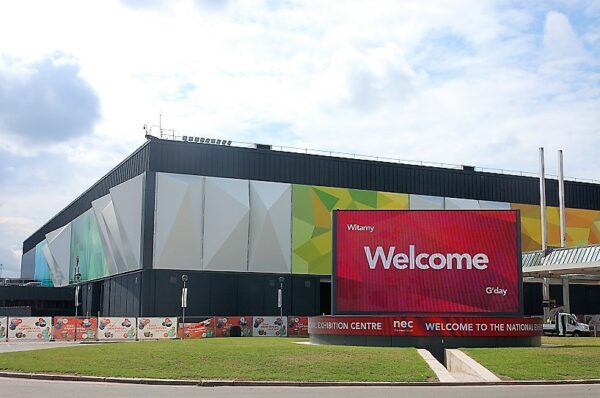

We were approached by the NEC to give the exteriors of Halls 1 and 5 an exciting new look as part of their strategic transformation called ‘project face-lift’.

The project consists of a series of translucent fabric pyramids inter-spaced with dramatic printed fabric panels. On the steel frame forming the pyramids we installed colour change LED back-lighting to allow the client to develop a series of pre-programmed light shows.

The graphics are the largest example in the UK of a specialist long life printing technique developed specifically for architectural use.

It was a challenging programme for the installation team, with a deadline of completion before the start of the Autumn show season.

The project took only 5 months from design through to installation. Our client was delighted that we finished a week ahead of schedule and on budget. This was largely achieved due to the proactive client team and the support of our regular subcontractors.

With the addition of the Bear Grylls Adventure Centre, a Casino, Conference Centre and two new Hotels the NEC is gearing up to be a major destination in the UK.

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…

Over the past 12 months, a new landmark has arrived on the Portsmouth shoreline – Land Rover BAR’s headquarters, a building which will play host to a team that is making a bid to win sailing’s top prize. Developing a yacht and crew good enough to enter and win the America’s Cup requires a multi-million-pound investment.

Using modern methods of construction – and with technologies incorporated into the design to seek carbon neutral credentials – Ben Ainslie Racing sought to commission a home that brings together the three key functions of boat design and team training; boat building, a visitor and education centre. HGP Architects who designed the Spinnaker Tower, were commissioned to design and deliver a unique and functional building on the Camber site in Portsmouth.

Base Structures was asked initially by HGP Architects to provide a semi-transparent fabric cladding wrap to stretch around a robust structure of a combination of glass reinforced concrete and glazing with the fabric having the capacity to be externally back lit.

As designs developed, Base were also commissioned to provide a triple skin ETFE cushion insulated atrium roof system to provide a high level of light through into the central core of the building, together with an internal retractable blind system to handle solar gain and glare.

Hamish Calder – Ben Ainsley Racing

Matthew Williams – Architect, HGP Architects

Vivienne Conway – Architect, HGP Architects

Kevin Hemmings – Architect, Base Structures

Fraser Shirley – Project Manager, Base Structures

Ferrari Soltis 86 fabric mesh was specified for the external vertical cladding to allow a degree of transparency both sides, with the roof panels using a sold PVC Mehler 7211 fabric to allow for drainage. The ETFE triple layer system provided by Vector Foiltec, achieves a U value of 1.96 W/m2k with a light transmittance of 87%.

“Home of Ben Ainslie Racing Built to BREEAM excellent standards, a purpose-built facility housing all of the team’s activities from design to sailing, sports science to marketing – a showcase for sport, innovation, technology and sustainability in the heart of Portsmouth.”

Vital Statistics