Designed exclusively for couples, The Rendezvous Hotel is an idyllic and intimate Caribbean hideaway, set on a beautiful two-mile stretch of white sandy beach and surrounded by seven acres of tropical gardens. To cover an outdoor seating area where couples and honeymooners enjoy the finest cuisine right at the water’s edge, an open tensile fabric canopy was needed to provide both solar shade and the occasional rain protection.

Based on one of our previous projects at Priory School, our pre-designed Malvern canopy was modified for this restaurant to ensure its high points were in the middle of the structure whilst its low points were on the edge. This was for practical reasons to ensure that staff members could easily access the seating area without the canopy getting in the way whilst serving customers. Also, due to the surrounding marine environment, we needed to use a very high specification of stainless steel to avoid any rusting. Finally, due to the risk of occasional hurricanes and high wind speeds, the restaurant needed the ability to dismount the fabric when necessary.

We may be biased, but the Toes in the Sand restaurant would definitely make it onto our bucket list. The addition of a tensile fabric canopy creates a more modern and stylish look to the restaurant whilst providing an intimate atmosphere for diners… who knew tensile fabric could be so romantic!

As part of their recent extensive renovations, Twycross Zoo wished to create a new focal point to the zoos entrance. To this end they commissioned a new visitor centre comprising a café, bar, gift shop and two new exhibits, one displaying their world renowned collection of wading birds and the other a flagship enclosure displaying the brand new snow leopard collection. Base were involved in the design and installation of this snow leopard enclosure.

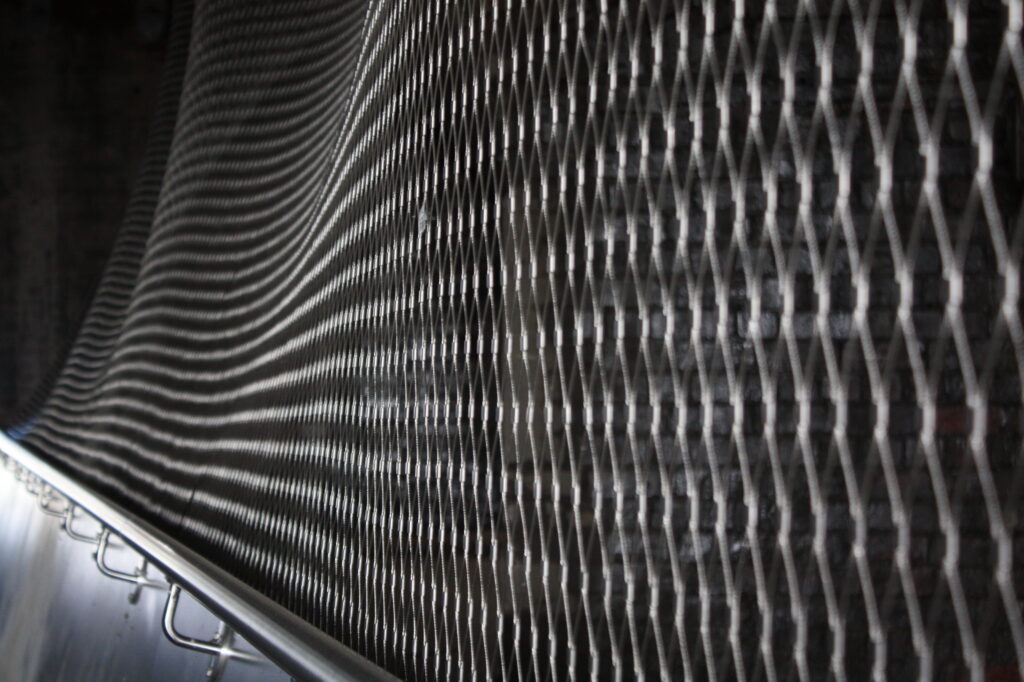

The snow leopard enclosure faces onto the new visitor centre and is formed from galvanized steel perimeter posts and tie rods, supported by stainless steel cables and netting, keeping the people of Leicestershire safe from the snow leopards, and vice versa.

The snow leopards of Twycross zoo settled into their enclosure quickly and comfortably while visitors can enjoy the beautiful animals safely.

For our clients who run and manage zoos, animal welfare is their top priority. Most zoos exist as an opportunity not just for the public…

Following the success of the London 2012 Games, the Olympic Park in Stratford underwent another transformation to turn it into what is now known as Queen Elizabeth Olympic Park, fully reopening to the public in April 2014. Base were tasked with transforming an existing underpass in the south of the park (identified with the snappy name of U06) that was used as a pedestrian link to Pudding Mill Lane station. Consisting of a series of brick arches measuring 60 metres long, the underpass traverses directly underneath the Great Eastern main railway line.

Base fabricated and installed a cablenet supported lighting system consisting of 61 waterproof fluorescent luminaires suspended from a tensioned steel wire catenary with electro-polished fittings. Running the length of the underpass the cablenet is fixed to the existing brick structure of the underpass with cintec anchors. Elements from an existing cablenet structure on the Park that had been dismantled were reused to maximise value for money and sustainability for the project.

An additional infill webnet closure panel was also set up along a section of the underpass. Running from the floor to fixing points on the vertical wall of the underpass, the flexibility of the mesh was utilised to create undulations as it attached to high and low points on the wall.

A wide range of shapes and fabrics for the internal structures were employed ranging from internally lit tensile lycra cones to multi-coloured silk flags for a Himalayan inspired feature.

Tapered prisms were suspended above the check out desks wrapped in a leaf patterned fabric. A golden brown silk fabric was tensioned onto lightweight leaf shaped frames and was grouped on branches as well as being suspended in an array of twenty above a main aisle. Finally in an external courtyard triangular mesh fabric sails were tensioned between stripped bark timber poles set in concrete foundations to act as a sun shade.

Van Hage Garden Park is an excellent example of the range of fabrics and forms that can be used to good effect in one project.

With a maximum of 24 guests allowed at any one time and spacious bedrooms with en-suite bathrooms, this is the ultimate safari experience.

Catering for the luxury holiday market, Virgin Limited Edition is Sir Richard Branson’s private collection of beautiful retreats – including a private island, ski chalet, mountain retreat, catamaran, game reserve and a restaurant & private club. It is for the latest addition to the portfolio, Mahali Mzuri, that we were approached to help make extra special, a collection of 12 luxury tented suites in the Maasai Mara in Kenya.

A conic PVC fabric roof with a cantilevered arch sits atop a raised platform, ensuring that the wildlife can only get so close to the snoozing human beings inside. A dark grey PVC fabric enables the structures to blend into the surrounding environment somewhat, preventing the new development from dominating the landscape. Detail designed and manufactured here in the UK, the bespoke structures were then successfully installed by a local workforce.

With a maximum of 24 guests allowed at any one time and spacious bedrooms with en-suite bathrooms, this is the ultimate safari experience.

This striking twin cone fabric structure shelters a new play area at the newly refurbished White Rose Centre in Leeds.

The design brief was to let as much light as possible through into the play area hence the choice to go for a silicone glass coated fabric. The design also had to accommodate some significant changes in ground level and very tight boundary conditions.

With careful preplanning the installation was smoothly achieved with two cranes in a short weather window. NG Bailey who manage the centre were very happy with the works “Very professional and well organised, brilliant!” Alan Barnsdale, NG Bailey.

We manufactured and installed The Hub’s canopy which is suspended from the surrounding buildings, a tricky feat of engineering and a test of our 3D modeling systems. The hub is constructed from a three chord rolled steel truss which is clad with steel panels and supports a state of the art inflatable ETFE cushion.

The Hub will be the first permanent outdoor 3D sound performance space in the country. The Hub’s 3D sound system can be configured to broadcast any live or recorded sound. A unique ambient ‘soundscape’ has been composed for The Hub by Illustrious Company. The soundscape will provide an immersive sound experience and will include elements of recordings made in and around Workington in October 2006.

Manchester International Festival (MIF) is an artist-led, commissioning festival which presents new works from the performing arts, visual arts and popular culture. As part of the 2009 festival, Zaha Hadid Architects was commissioned to design a contemporary salon to house solo performances of Johann Sebastian Bach’s music. The installation was to be housed in a 25m x 17m ‘black box’ in the Manchester Art Gallery. Zaha Hadid Architects responded with a stunning design consisting of a 110m long white ribbon which would wrap itself around both the stage and the audience, creating a dynamic yet intimate performance space.

Zaha Hadid is one of the most extraordinary, innovative and creative designers to work with textile architecture. Each piece designed by her team is a head turning, award winning revelation. We have collaborated on a number of projects and each time our creativity in design and manufacture as well as the technical capabilities in the fabric are challenged to their very limits. The results are awe inspiring brilliance.

Jack Thompson, Technical Director, MIF

Tracey Low, Senior Producer, MIF

Melodie Leung, Architect, Zaha Hadid Architects

Gerhild Orthacker, Architect, Zaha Hadid Architects

Kevin Hemmings, Architect, Base Structures

Andy Traynor, Installation Director, Base Structures

Tony Hogg, Engineer, Tony Hogg Design

Benedict Whybrow, Designer, Tony Hogg Design

Michael Whitcroft, Acoustic Engineer, Sandy Brown Associates

Nick Croker & Paul Thomas, Site Supervisors, Base Structures

Having already successfully collaborated on the Serpentine Gallery project, Zaha Hadid Architects approached Base to gain the team’s technical expertise on the design’s buildability – with the performance of the ‘ribbon’ being pivotal to its function. Transport ability was another consideration for Base, as the installation would also be reinstalled in other venues.

Base’s recommendation was to combine a light aluminium frame with a stretch Lycra® fabric skin. With preliminary costs coming within budget, Zaha Hadid Architects commissioned Base to develop the design through to cost certainty.

The first challenge for Base was to transform the architect’s complex 3D model into a buildable structure that retained all the fluidity of the original design. With the help of experienced tensile engineers Tony Hogg Design, Base constructed a framework that replicated the model exactly. And to be certain of the fabric’s suitability, Base fabricated and wrapped a prototype section of the frame to test fabric compensations.

For the ‘ribbon’ to perform as intended, it was imperative that a smooth change of curvature was maintained throughout the structure. So Base’s solution featured a series of eye shaped rib frames, connected with a top and bottom rail each rolled to a specific radius. Speed of installation was essential too, so turned nylon spigots were employed to connect the frames with a push fit connection. Likewise the fabric was designed to be applied rapidly by only having nine ‘fields’ which were zipped together with a discrete plastic closure, utilising Base’s expertise from the banner finishing side of its business.

The frame was hung by 2.5mm stainless steel cables from suspension points in the gallery ceiling, incorporating an easy to adjust fastener. Base also supplied the stage platform and fitted rigid acoustic reflector panels inside parts of the ribbon, directed by acoustic engineers, Sandy Brown Associates. The structure was installed in three days with two teams of four riggers, working day and night shifts.

The result was a single continuous ribbon which swirled around one of the main rooms in the Manchester Art Gallery, creating layered spaces cocooning both performers and the audience. Base’s successful realisation of Zaha Hadid Architect’s design was largely due to the combined experience of the team, ranging from engineering; detail design; fabrication of the frame; assembly of the fabric; and the professional site crew. The project’s triumph was also recognised by one arts critic in particular, stating that the structure not only worked as a sculptural object but acoustically as a chamber music venue. The structure has since visited the Amsterdam Festival in 2010 and is due to continue its tour, scheduled for a visit to Abu Dhabi in March 2011.

The Millennium Dome was originally commissioned to mark the beginning of the new Millennium, also forming a key element in the redevelopment of the entire Greenwich Peninsula. Intended to be an iconic and celebratory structure offering an enormous and flexible space, it has since been redeveloped and operated by AEG and rebranded as The O2 – one of the world’s most popular music and entertainment venue. In July 2011 planning permission was granted for the construction of a roof walkway across the top of the structure, designed by Rogers Stirk Harbour + Partners with Buro Happold. The roof walk, “Up at the O2” is a partnership between AEG and O2, the UK’s leading communication company.

Alistair Wood, Senior Vice President of Real Estate & Development, AEG

Eamonn Wall, Project Director, ISG

Jon Clayden, Senior Construction Manager, ISG

Tim Finlay, Senior Structural Engineer, Buro Happold

Mark Smith, Director/Head of Projects, Base Structures

The climbing experience begins on the south side of The O2 where a staircase and glass lift connect to a platform 7.5m high. From here the fabric walkway suspends above the existing fabric structure to its apex with a lanyard cable and hand rail running the full length of the walkway. Climbers will be provided with ‘climb suits’ and harnesses enabling them to be attached directly to the cable as they climb to the top. At The O2’s apex a 12m diameter viewing platform with a panorama plate directs climbers to key London landmarks. The roof walk then extends to the north side where climbers descend to ground level.

With Buro Happold already acting as lead consultant, Base Structures were next to be appointed by ISG to ensure the successful and timely delivery of the scheme. Responsible for delivering the detail design, fabrication and construction of the unique cable tensioned walkway and central viewing platform, Base immediately began extensive surveying of the site and prototyping of the proposed design principals.

The climbing experience begins on the south side of The O2 where a staircase and glass lift connect to a platform 7.5m high. From here the fabric walkway suspends above the existing fabric structure to its apex with a lanyard cable and hand rail running the full length of the walkway. Climbers will be provided with ‘climb suits’ and harnesses enabling them to be attached directly to the cable as they climb to the top. At the O2’s apex a 12m diameter viewing platform with a panorama plate directs climbers to key London landmarks.

The roof walk then extends to the north side where climbers descend to ground level. The overall challenges of delivering this project were extensive – the integrity of the existing structure could not be affected; no hot works could be used on the fabric roof: and no crane in existence could reach far enough to fully access the site. As if the daunting challenge of realising the architect’s vision was not enough, there was also a very tight and immovable deadline to contend with – The O2 arena was due to be handed over for the London 2012 Games within a matter of months.

The technical challenges this project presented were considerable. The first problem to overcome was to ensure it was actually physically possible to walk up the fabric surface – no small feat given 30° inclines and the inclemency of the English weather. To help increase traction, fabric manufacturer Mehler created a bespoke PVC fabric for this project with a non-standard textured surface. Whilst this improved grip it soon became clear that more radical surface modifications would be needed on the steepest slopes, especially in the rain – the roof walk needed to be challenging but not impossible.

With no crane in existence having enough reach to access the centre of the O2, a unique system was designed to manually convey the 30 tonnes of tools and materials over the roof – pulling custom built sledges over a protective pvc runway laid on the surface of the existing fabric roof, preventing any damage to the fragile surface. Duncan Baird, Installations Manager at Base explains “We manufactured two different types of sledge, one to transport the viewing platform steelwork and another for the walkway fabric with the size, shape and configuration carefully calculated to safely spread the largest loads. As far as we are aware no one else has used this type of system before.”

With no hot works allowed on the fabric roof the steelwork for the viewing platform was fabricated to simply bolt together like a huge Meccano kit. Support cables attached to the yellow masts take the weight of the steelwork, again ensuring no loads are applied to the existing roof surface. Only with the viewing platform completed could the fabric walkway installation now begin, from the centre of the structure down to the ground.

Back at Base HQ manufacture of the fabric continued in earnest with 75 panels making up the whole walkway, including the side wing panels. The panels for the steepest sections of the walkway required every single piece of additional ribbing to be positioned and welded by hand, an enormous task with over 3 kilometres of ribbing in total to attach.

Before going to site every panel was fitted with cables and clamps and pre-tensioned in the factory on a special rig for quality control tests. A total of 3 kilometres of cable runs through the edges of the walkway fabric and nearly 4,000 clamps are used to attach the panels to the supporting cables on The O2. The mammoth task of fitting all this hardware in the factory meant that the rigging team on site could simply lift each section into place and secure it to the previous panel and support cables.

As a continual supply of the fabric panels ready for install reached site, one of the biggest problems that was to face the rigging team soon became apparent – the weather. High winds make working on such an exposed site with huge pieces of fabric unsafe and this cost the team a significant number of days. Whilst it is generally only wind that causes delays for tensile fabric installations, Mark Smith, Head of Projects at Base, explains how things got even trickier “It was always going to be a challenge but not one that we weren’t used to. However, we weren’t expecting the wettest ever April on record, which meant we had to work most weekends throughout the project in order to recover the lost time.”

After pulling out all the stops the walkway panels were all finally in place and the entire structure could be carefully tensioned out – a delicate procedure that must be coordinated perfectly to prevent uneven loads being applied to the masts. As the walkway revealed itself in its final completed form, and with all hands on deck to complete the finishing touches in time for the grand opening, it became clear that the race had been won – just.

On 23rd May 2012 Up at the O2 was officially announced to the world, with the first paying climbers making the journey over The O2 on 21st June. With the works completed on time the venue could now be safely handed over for the London 2012 games, to the great relief of all involved.

London 2012 Games Basketball Arena is a structure of heroic proportions. Innovative and efficient, the structure had to deliver on many levels, as it was the largest temporary structure on the Olympic Park.

Awesome seems a fitting word to describe it. The individual roof panels alone weighed 3/4 of a tonne each. A feat to behold, it was also a feat to install! If its awe inspiring presence in the Park wasn’t enough, the stunning structure became a London 2012 Games showman when it reflected the planned lighting display.

A ‘skeleton’ frame measuring 30m high and spanning 96m, swathed in 20,000m2 of crystal white tensile fabric made by Verseidag, the arena resembles a magnificent, gigantic ice cube.