Our client approached us to assist them with a PVC roof structure over a Salt Barn that had reached the end of its lifespan.

We carried out a methodical removal of the old roof and gable panel and supplied and installed a new 1200m2 panel to the structure.

Given the size of the panel and the tricky crane lift this produced, the installation was particularly challenging during a windy autumn period. Further challenges presented were ensuring the salt was kept dry between the removal and replacement of the roof.

With a fixed deadline and delivery of several thousand tonnes of salt looming, we had to work swiftly and efficiently, using the old removed fabric to provide temporary protection.

The beginning of 2019 brought a lot of stormy weather to Liverpool docks and left Liverpool Port Authority warehouse looking a little worse for wear. We are no strangers to the Liverpool docks site as back in 2013 Base Structures designed and manufactured the 22,000m² of tensile fabric that covers the warehouse skeleton steel structure.

A small amount of damage was sustained from within the building that wasn’t attended to promptly, the stormy weather came, picked and pulled at the cladding. The devastation is all too clear in the pictures below.

Base was called in to assess the structure. We then stabilised the cladding to prevent further damage from the second storm that was expected a few days later.

We removed all damaged components, re-instated where we could, replaced what was not serviceable and ultimately brought the structure back to life.

As tensile structures such as this are an investment we do recommend regular maintenance to ensure they fulfil their design life and continue to look good.

Stunning architecture has become a trademark of the modern Olympic and Paralympic Games, with environmental credentials being of paramount importance. As such these three structures are not only at the forefront of contemporary design, they are also fully demountable and relocatable, amply fulfilling these criteria. Together they hosted the Shooting, Paralympic Shooting and Paralympic Archery events. The set consisted of the 25 meter, Combined 50 & 100 meter and the Finals Shooting Ranges.

Each event structure is individually identified by the bright discs of colour which are set into the high and low points that create the undulations in the facades. The Orange themed Finals building measures in at a massive 25m x 47m x 50m, requiring 16,000m2 of fabric to fully clothe it inside and out. The Magenta themed Combined Range measuring 10m x 20m x 106m, requires 9,000m2 of fabric and the blue themed 25m Range building measuring 25m x 55m x 10m, 5,000m2. The high level discs incorporate ventilation openings whilst the ground level ones identify doorways for ingress through similarly coloured tunnels to the sporting arenas.

IFAI International Achievement Award 2013 Winner.

Lords cricket ground, owned by Marylebone Cricket Club, is regarded as the world wide spiritual home of cricket. To ensure the Ground remains not only world-famous but a truly world-class sporting venue, a multi-million pound overhaul was undertaken, part of which included the upgrade of the Mound Stand canopy which after eighteen years of sterling service had reached the end of it’s designed life span.

John Cutlack, Director Capita Symonds

Tony Hogg, Director, Tony Hogg Design Ltd

Mark Smith, Contracts Director, Base Structures

Chris Ives, Project Manager, Base Structures

We were briefed by Capita Symonds, the appointed representatives of Marylebone Cricket Club, to remove, redesign, manufacture and install the new tensile fabric roof over the Mound Stand, a monumental task that would not simply replace the old canopy but provide significant structural improvements through the use of more advanced materials and up-to-date design detailing. As such the replacement canopy would be expected to last significantly longer than the old one.

A fundamental part of the contract win was our ability to ensure the recycling of the old canopy and so we partnered with Serge Ferrari (suppliers of the fabric for the new canopy), who have developed and built the Texyloop PVC recycling factory in South Eastern France. The recycling of the old canopy led to Base Structures achieving a finalist Building award for Sustainability in 2006.

Base Structures were able to provide the client with a methodology that ensured we would meet the tight deadlines, budgets and planning restrictions. This was made possible through the accurate surveying of the existing structure to ensure the replication of the iconic shape, and through the use of innovative access methods. It was essential that the project was undertaken and completed in one closed season so that our works did not interfere with or delay scheduled cricket matches.

The first task was to remove the old canopy, in itself a huge job. The biggest problem faced by our team concerned how to fully access the canopy structure as it overhangs a busy main road and is closely neighboured by residential buildings.

The solution we identified required the use of Working Platform Nets. These netting systems are engineered to ensure the safety of the operatives working on and below them is not compromised and they proved to be incredibly cost effective by reducing the man hours needed working at height, when compared to traditional means of access such as scaffolding. Once the netting was installed by our fully qualified rope access team, non-IRATA trained personnel could then access the work areas in complete safety. The old canopy came down surprisingly quickly once the netting allowed easy access to the structure, especially considering the amount of fabric involved.

Next a detailed survey of the existing steelwork enabled our design department to accurately recreate the iconic structure within our specialist CAD software, from which we produced the cutting patterns and finalised the detail design.

It was necessary to redesign and upgrade all the fixtures and fixings on the existing structure to take into account advancements in tensile fabric over the previous eighteen years, ensuring that they were all brought up to current best practice standards. The new PVC membrane itself was a higher specification fabric than the original canopy, using higher quality PVDF lacquers to guarantee a longer life span. As part of this extensive upgrading process all the existing structural steelwork was repainted before the new canopy was installed.

The old canopy was originally made in sections that were joined together using metal fixtures. Taking advantage of the opportunity to redesign the canopy and to improve the aesthetics, the new 1400 sq metre fabric membrane was manufactured and installed as a single piece of fabric. This improvement resulted in no site joints along the front of the canopy, significantly enhancing the overall appearance.

Once manufactured the installation of the new canopy began in earnest; the fact our rigging team had removed the old canopy gave us a flying start when it came to installing the new one, since they already knew the structure inside and out. After the new canopy was lifted over the multiple masts in one piece, our rigging team made short work of the installation.

The entire project was successfully completed ahead of schedule and below budget, no easy task considering the scale and complexity of the project. The replacement canopy not only restored the stand to its former glory but also improved the aesthetics and expected life span of the structure. Marylebone Cricket Club were extremely happy with the refurbishment and continue to use Base Structures for regular maintenance of this most iconic of structures.

Our client was looking for a demountable wall system to their new exhibition hall structure built to house the National Cold War Exhibition.

We designed, manufactured and installed the fabric panels and the associated steelwork. We also installed the steel framework and trusses.

The tensile fabric structure fulfills a practical purpose as removable walling, as well as being a dynamic use of interior space allowing light into the building.

The ‘Lilas’ leaf and petal design on the fabric was by the Pitzker-Prize winning architect, Zaha Hadid. It is 5.5 meters in height and is formed by three identical tensile fabric parasols arranged around a central point.

The clients brief was to pattern, manufacture and install this unique tensile fabric structure as a focal point for the Serpentine Gallery’s ‘Summer Party’.

The centrepiece of the new Winton Gallery at London’s Science Museum is a trio of fabric pod sculptures clustered around the tail and wings of a vintage Handley Page aircraft.

The organic fabric forms and the layout of the surrounding gallery are an interpretation by Zaha Hadid Architects of the airflow vortices that would be generated by the plane.

We installed the complex structures, each consisting of a curved aluminium tubular frame suspended from the ceiling onto which two skins of semi-translucent PVC coated polyester are tensioned.

Multiple LED lighting strips are mounted between the skins and contribute to the stunning overall effect. Due to the complexity of the structures, one of the twin skins had to be split and fed through the apertures created by the other skin before being joined together with two hidden zips.

The tensioning system is hidden behind double curved aluminium cover plates.

Base were also responsible for the installation of the interpretation surfaces adjacent to each exhibit.

Image credits: © Nick Guttridge

Designed exclusively for couples, The Rendezvous Hotel is an idyllic and intimate Caribbean hideaway, set on a beautiful two-mile stretch of white sandy beach and surrounded by seven acres of tropical gardens. To cover an outdoor seating area where couples and honeymooners enjoy the finest cuisine right at the water’s edge, an open tensile fabric canopy was needed to provide both solar shade and the occasional rain protection.

Based on one of our previous projects at Priory School, our pre-designed Malvern canopy was modified for this restaurant to ensure its high points were in the middle of the structure whilst its low points were on the edge. This was for practical reasons to ensure that staff members could easily access the seating area without the canopy getting in the way whilst serving customers. Also, due to the surrounding marine environment, we needed to use a very high specification of stainless steel to avoid any rusting. Finally, due to the risk of occasional hurricanes and high wind speeds, the restaurant needed the ability to dismount the fabric when necessary.

We may be biased, but the Toes in the Sand restaurant would definitely make it onto our bucket list. The addition of a tensile fabric canopy creates a more modern and stylish look to the restaurant whilst providing an intimate atmosphere for diners… who knew tensile fabric could be so romantic!

Following the success of the London 2012 Games, the Olympic Park in Stratford underwent another transformation to turn it into what is now known as Queen Elizabeth Olympic Park, fully reopening to the public in April 2014. Base were tasked with transforming an existing underpass in the south of the park (identified with the snappy name of U06) that was used as a pedestrian link to Pudding Mill Lane station. Consisting of a series of brick arches measuring 60 metres long, the underpass traverses directly underneath the Great Eastern main railway line.

Base fabricated and installed a cablenet supported lighting system consisting of 61 waterproof fluorescent luminaires suspended from a tensioned steel wire catenary with electro-polished fittings. Running the length of the underpass the cablenet is fixed to the existing brick structure of the underpass with cintec anchors. Elements from an existing cablenet structure on the Park that had been dismantled were reused to maximise value for money and sustainability for the project.

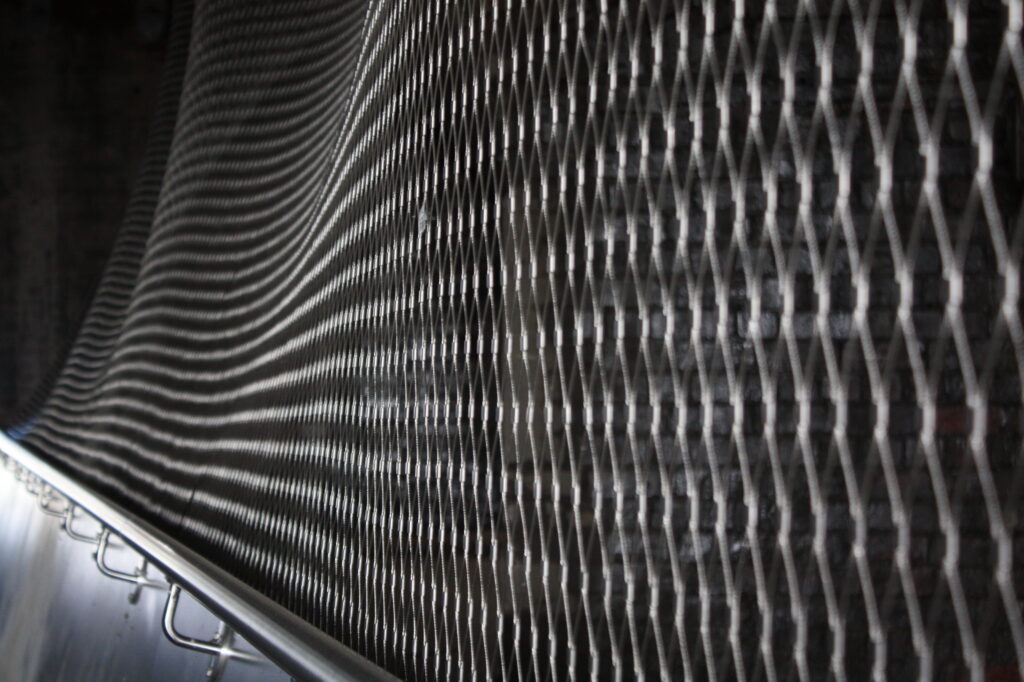

An additional infill webnet closure panel was also set up along a section of the underpass. Running from the floor to fixing points on the vertical wall of the underpass, the flexibility of the mesh was utilised to create undulations as it attached to high and low points on the wall.

Catering for the luxury holiday market, Virgin Limited Edition is Sir Richard Branson’s private collection of beautiful retreats – including a private island, ski chalet, mountain retreat, catamaran, game reserve and a restaurant & private club. It is for the latest addition to the portfolio, Mahali Mzuri, that we were approached to help make extra special, a collection of 12 luxury tented suites in the Maasai Mara in Kenya.

A conic PVC fabric roof with a cantilevered arch sits atop a raised platform, ensuring that the wildlife can only get so close to the snoozing human beings inside. A dark grey PVC fabric enables the structures to blend into the surrounding environment somewhat, preventing the new development from dominating the landscape. Detail designed and manufactured here in the UK, the bespoke structures were then successfully installed by a local workforce.

With a maximum of 24 guests allowed at any one time and spacious bedrooms with en-suite bathrooms, this is the ultimate safari experience.