The centrepiece of the new Winton Gallery at London’s Science Museum is a trio of fabric pod sculptures clustered around the tail and wings of a vintage Handley Page aircraft.

The organic fabric forms and the layout of the surrounding gallery are an interpretation by Zaha Hadid Architects of the airflow vortices that would be generated by the plane.

We installed the complex structures, each consisting of a curved aluminium tubular frame suspended from the ceiling onto which two skins of semi-translucent PVC coated polyester are tensioned.

Multiple LED lighting strips are mounted between the skins and contribute to the stunning overall effect. Due to the complexity of the structures, one of the twin skins had to be split and fed through the apertures created by the other skin before being joined together with two hidden zips.

The tensioning system is hidden behind double curved aluminium cover plates.

Base were also responsible for the installation of the interpretation surfaces adjacent to each exhibit.

Image credits: © Nick Guttridge

Our brief was to install temporary wraps to the columns at the entrance of Tate Britain, as a special feature linking in with the David Batchelor artwork exhibition taking place at the time. The wraps acted not only as an advertisment for the exhibition but were a vibrant and imaginative use of the existing buildings architecture.

The project was more complicated than it looked as each natural stone column is unique and therefore each one had to be individually surveyed by our climbers before patterning the fabric to suit. We manufactured the wraps from fabric printed to the colours specified by the artist and installed them at night, once again using ropes access techniques. The Tate Britain Museum were extremely pleased with the result of the finished product and the high quality.

A wide range of shapes and fabrics for the internal structures were employed ranging from internally lit tensile lycra cones to multi-coloured silk flags for a Himalayan inspired feature.

Tapered prisms were suspended above the check out desks wrapped in a leaf patterned fabric. A golden brown silk fabric was tensioned onto lightweight leaf shaped frames and was grouped on branches as well as being suspended in an array of twenty above a main aisle. Finally in an external courtyard triangular mesh fabric sails were tensioned between stripped bark timber poles set in concrete foundations to act as a sun shade.

Van Hage Garden Park is an excellent example of the range of fabrics and forms that can be used to good effect in one project.

With a maximum of 24 guests allowed at any one time and spacious bedrooms with en-suite bathrooms, this is the ultimate safari experience.

We manufactured and installed The Hub’s canopy which is suspended from the surrounding buildings, a tricky feat of engineering and a test of our 3D modeling systems. The hub is constructed from a three chord rolled steel truss which is clad with steel panels and supports a state of the art inflatable ETFE cushion.

The Hub will be the first permanent outdoor 3D sound performance space in the country. The Hub’s 3D sound system can be configured to broadcast any live or recorded sound. A unique ambient ‘soundscape’ has been composed for The Hub by Illustrious Company. The soundscape will provide an immersive sound experience and will include elements of recordings made in and around Workington in October 2006.

Manchester International Festival (MIF) is an artist-led, commissioning festival which presents new works from the performing arts, visual arts and popular culture. As part of the 2009 festival, Zaha Hadid Architects was commissioned to design a contemporary salon to house solo performances of Johann Sebastian Bach’s music. The installation was to be housed in a 25m x 17m ‘black box’ in the Manchester Art Gallery. Zaha Hadid Architects responded with a stunning design consisting of a 110m long white ribbon which would wrap itself around both the stage and the audience, creating a dynamic yet intimate performance space.

Zaha Hadid is one of the most extraordinary, innovative and creative designers to work with textile architecture. Each piece designed by her team is a head turning, award winning revelation. We have collaborated on a number of projects and each time our creativity in design and manufacture as well as the technical capabilities in the fabric are challenged to their very limits. The results are awe inspiring brilliance.

Jack Thompson, Technical Director, MIF

Tracey Low, Senior Producer, MIF

Melodie Leung, Architect, Zaha Hadid Architects

Gerhild Orthacker, Architect, Zaha Hadid Architects

Kevin Hemmings, Architect, Base Structures

Andy Traynor, Installation Director, Base Structures

Tony Hogg, Engineer, Tony Hogg Design

Benedict Whybrow, Designer, Tony Hogg Design

Michael Whitcroft, Acoustic Engineer, Sandy Brown Associates

Nick Croker & Paul Thomas, Site Supervisors, Base Structures

Having already successfully collaborated on the Serpentine Gallery project, Zaha Hadid Architects approached Base to gain the team’s technical expertise on the design’s buildability – with the performance of the ‘ribbon’ being pivotal to its function. Transport ability was another consideration for Base, as the installation would also be reinstalled in other venues.

Base’s recommendation was to combine a light aluminium frame with a stretch Lycra® fabric skin. With preliminary costs coming within budget, Zaha Hadid Architects commissioned Base to develop the design through to cost certainty.

The first challenge for Base was to transform the architect’s complex 3D model into a buildable structure that retained all the fluidity of the original design. With the help of experienced tensile engineers Tony Hogg Design, Base constructed a framework that replicated the model exactly. And to be certain of the fabric’s suitability, Base fabricated and wrapped a prototype section of the frame to test fabric compensations.

For the ‘ribbon’ to perform as intended, it was imperative that a smooth change of curvature was maintained throughout the structure. So Base’s solution featured a series of eye shaped rib frames, connected with a top and bottom rail each rolled to a specific radius. Speed of installation was essential too, so turned nylon spigots were employed to connect the frames with a push fit connection. Likewise the fabric was designed to be applied rapidly by only having nine ‘fields’ which were zipped together with a discrete plastic closure, utilising Base’s expertise from the banner finishing side of its business.

The frame was hung by 2.5mm stainless steel cables from suspension points in the gallery ceiling, incorporating an easy to adjust fastener. Base also supplied the stage platform and fitted rigid acoustic reflector panels inside parts of the ribbon, directed by acoustic engineers, Sandy Brown Associates. The structure was installed in three days with two teams of four riggers, working day and night shifts.

The result was a single continuous ribbon which swirled around one of the main rooms in the Manchester Art Gallery, creating layered spaces cocooning both performers and the audience. Base’s successful realisation of Zaha Hadid Architect’s design was largely due to the combined experience of the team, ranging from engineering; detail design; fabrication of the frame; assembly of the fabric; and the professional site crew. The project’s triumph was also recognised by one arts critic in particular, stating that the structure not only worked as a sculptural object but acoustically as a chamber music venue. The structure has since visited the Amsterdam Festival in 2010 and is due to continue its tour, scheduled for a visit to Abu Dhabi in March 2011.

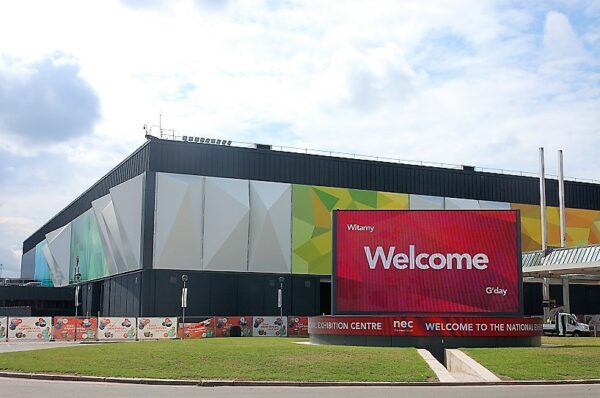

We were approached by the NEC to give the exteriors of Halls 1 and 5 an exciting new look as part of their strategic transformation called ‘project face-lift’.

The project consists of a series of translucent fabric pyramids inter-spaced with dramatic printed fabric panels. On the steel frame forming the pyramids we installed colour change LED back-lighting to allow the client to develop a series of pre-programmed light shows.

The graphics are the largest example in the UK of a specialist long life printing technique developed specifically for architectural use.

It was a challenging programme for the installation team, with a deadline of completion before the start of the Autumn show season.

The project took only 5 months from design through to installation. Our client was delighted that we finished a week ahead of schedule and on budget. This was largely achieved due to the proactive client team and the support of our regular subcontractors.

With the addition of the Bear Grylls Adventure Centre, a Casino, Conference Centre and two new Hotels the NEC is gearing up to be a major destination in the UK.

As part of an exciting £4.5 million transformation of Birmingham’s NEC, Base Structures has installed a stunning fabric façade to the exterior of Halls 1…