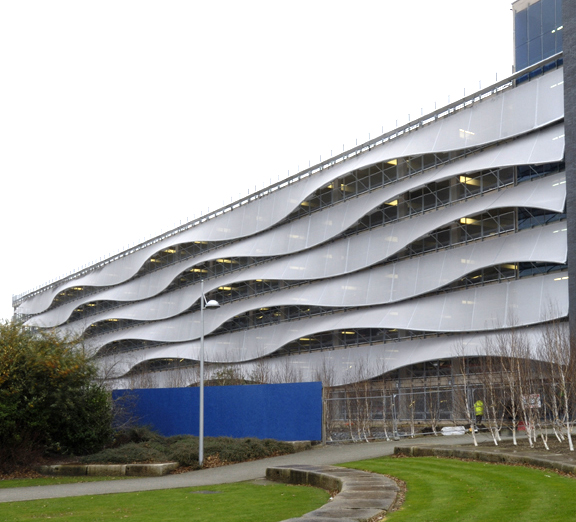

Cardiff Bay is Europe’s largest waterfront development. The Bay area was created by the Cardiff Barrage, one of the largest civil engineering projects in Europe during the 1990s and the subsequent regeneration of the area is widely regarded as one of the great success stories in the United Kingdom. As part of the continuing success story of Cardiff Bay, a newly built 1238 space multi-storey car park in a prominent location required status as a landmark building. The £11m car park was the first phase of a £150m development and utilises cutting edge 21st century design to reflect the rich nautical heritage of the area.

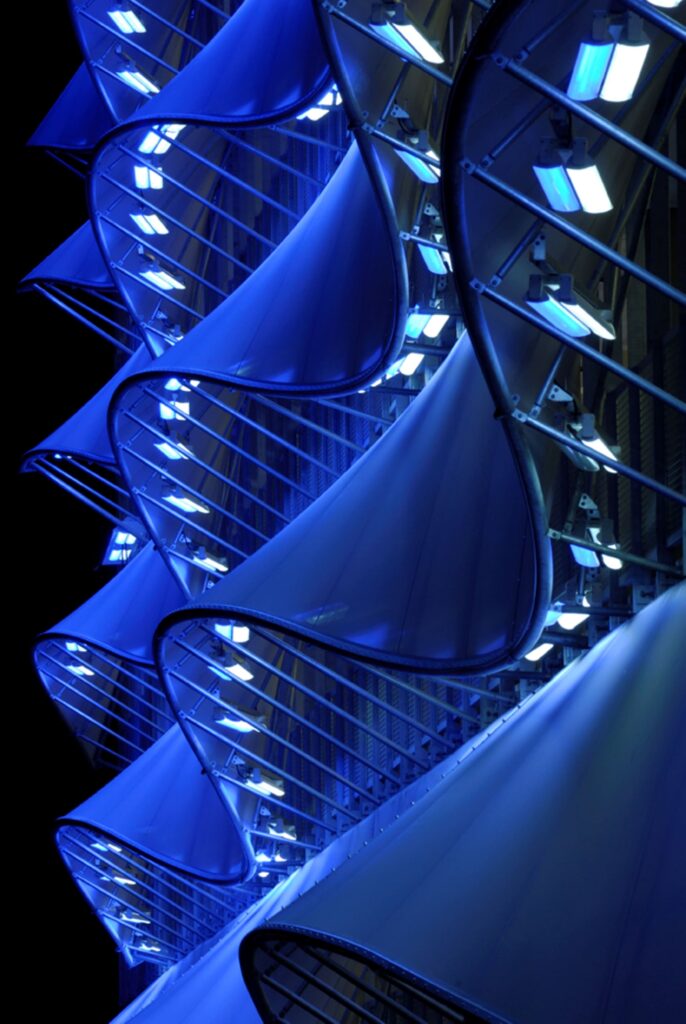

The rectangular, box like car park was to be completely transformed by a series of six 120m long scalloped tensile fabric ribbons running parallel across the entire width of building, a stunning contemporary design by Scott Brownrigg Architects. The pulsing waves of fabric cascading down the front of the car park bring an otherwise unremarkable building, formed entirely by it’s function, dramatically alive with movement and a dynamic flair that most car parks could only dream of! Base Structures were approached by main contractor McAlpine Construction to use our specialist skills to detail design, manufacture and install the tensile fabric structure and lighting system.

Base Structures were selected to bring this vision into reality due to our proven expertise and excellent relationship with the main contractor. As well as undertaking the detail design, manufacture and installation of the fabric facades, we also collaborated closely with a specialist lighting company to create the impressive lighting scheme.

A silver mesh PVC fabric was selected for a number of reasons that were crucial to the successful function of the facade. A mesh fabric allows light and air to filter through into the car park, ensuring the facade that clothes the front of the building does not create a dark and exhaust filled cavern. From inside the car park it is possible to see through the mesh fabric to the outside world, retaining an open feeling inside a ‘clothed’ building, further enhanced by the wave design which inherently creates sizable openings that also serve to improve the airflow.

Because Base were involved with every aspect of the project, from the detail design through to the installation of the fabric and lighting, the completion of the facade was completed in approximately 10 weeks, on budget and on time. The installation of the ‘wavy’ steelwork that supports the fabric was a simple process completed by a six man team working on scaffold. 120 meter long Halfen channel had already been cast into the concrete structure of the building front, requiring us to simply secure the necessary fixing bolts at specific distances before attaching the framework. The installation of the tensile fabric and lighting system was completed next using eight men and cherry picker work platforms for access, with an electrician required to complete the final wiring once it was all in place. To finish the installation four of our rope access specialists were used to fit the bird protection equipment, including wires and spikes, preventing nesting on the lighting units and fouling on the fabric canopy.

The car park has been dubbed the coolest car park in Cardiff, an easy achievement one may think. For any public car park to be labelled as cool in the first place however, speaks volumes about the success of this tensile fabric transformation. The combination of tensile fabric and lighting is an extremely powerful one, especially when used to metamorphosise a building with a colour changing, three dimensional canvas. As far as we are aware this car park is the only example of it’s kind in the world.

As part of the Government’s initiative to roll out academies across the UK, Nottingham University and Leicestershire businessman David Samworth co-sponsored the building of a brand new secondary school in Nottingham – the Nottingham University Samworth Academy or NUSA.

One element of the architect’s design for the academy featured a cable supported, single skin clear ETFE roof over an unheated internal street. The roof’s main function, as well as providing a shelter, was to allow a high level of natural light to enter the street as it was going to be bordered by classrooms. The main contractor, Carillion plc, approached Base for its technical expertise to develop a solution that could deliver all the key functional and aesthetic effects in the architect’s proposal.

Base won the project on technical experience, by proposing a more robust single skin ETFE solution. By adapting the revolutionary TEXO® cladding system, designed by Tensoforma of Italy, Base proposed to deliver an innovative tensile fabric solution that would offer the required high light translucency (97%), while offering a 30-year design, life thanks to a more modular approach. Initially conceived as a vertical cladding panel, this was the first time that TEXO had been adapted as an alternative to a glazed solution by using single skin ETFE foil.

The design incorporates a single layer of ETFE foil mounted on an extruded aluminium frame, and uses a high tech plastomeric strip to keep the foil under constant tension, even under varying wind loads. The benefits of the system include a high translucency roof that is a fraction of the weight, and costs considerably less than a toughened glass alternative.

The TEXO® system is modular in that the frames can be built and covered in a controlled factory environment off-site and delivered as complete and finished units which are then fixed into a prepared structural steel frame and gutter system. As such the solution also offered a high degree of prefabrication, reduced expensive site time and featured low weight components, which greatly reduced the risk of damage to the ETFE foil and from injury on site.

Base undertook the complete design, manufacture and installation process, including the structural aluminium gutters and primary steel arches.

Base delivered a highly innovative solution that matched the aesthetic requirements with a robust build quality, offering a 30-year lifespan – all installed swiftly and cost-effectively, meeting the brief and budget. The architect was particularly delighted with the high light levels our solution achieved. The NUSA opened to its first pupils on Friday 4th September 2009, and the new building was officially opened by Dame Kelly Holmes DBE in September 2010.

Our brief was to provide a spectacular bar for VIPs and artists to service the O2 Venue. The fabric structure consists of four interlocking domes, two entrance tunnels, one of which encloses a staircase, and three conical column claddings.

Barrisol was specified as an ideal material to cope with the complex architectural geometries of each panel. The fabric in the domes is back lit and LED lights are built into the tunnel frames. Base Structures coordinated the complex design and detailing of the scheme and provided the steel frame onto which the Barrisol panels were fixed.

The ambitious design was fully realized to provide a unique chill out zone.

Ousedale School has been serving the community of Newport Pagnell, a small town within the borough of Milton Keynes, since 1963. In 2014 the school refurbished tired areas that included the History and ICT Block with a fresh, contemporary scheme. Extending the modern makeover outside, a fabric canopy was planned that would not only maximise the usable exterior space but to add an architectural flourish to the school grounds.

Drawing inspiration from our pre-designed, award winning Blencathra canopy we installed in nearby Campbell Park in Milton Keynes, we worked with the school to redesign the canopy to optimally suit their own requirements. A reduction in size from 16m to 12m resulted in the Blencathra 12m canopy that would sympathetically fit within the existing school landscape whilst still providing an impressive amount of shelter. Unlike it’s bigger brother in Campbell Park, the demountable side and rear walls were completely omitted to create a permanently open structure.

The canopy has proven to be a hit with the pupils and staff alike, providing a new focal point and an added sense of identity to the school grounds. A perfect lesson on the flexibility of tensile canopy design!

Built on the site of a former paper mill, this major new housing development in Waltham Forest provides a much needed mix of private sale, shared ownership and market rental homes to help ease the significant shortage of affordable housing in the Capital.

Part of the new build design included a spacious communial atrium that required discreet protection from the elements. A lightwieght single skin ETFE roof was specified that allows 97% light transmittance to penetrate through to the living space below, allowing significant savings of materials and cost. Measuring 39 metres in length and 7 metres wide, the ETFE roof is divided into bays measuring approximately 5.5 metres x 7 metres. Tensioned cables attached to the structural main beams ensures adequate support of the ETFE panels in high-loading conditions such as snow. The only problem with the perfectly tensioned ETFE film is that it is so discreet, most people won’t notice all our hard work!

Portrush is a seaside town in Northern Ireland, well known for it’s extensive sandy beaches and a favourite holiday destination for generations of tourists. In an effort to maintain the seafront as a jewel in the tourism crown, Coleraine Council have undertaken extensive redevelopment of the Station Square area in Portrush – this includes an amphitheatre used for public performances and entertainment on the seafront. Given the exposed location and lively meteorological conditions, a canopy formed an essential addition to the outdoor entertainment hub.

The fabric canopy from our pre-designed range is the Cambrian, which is manufactured in one complete piece and will withstand the worst weather Northern Ireland can muster. Indeed it is this weather that caused the only complications during installation, high wind speeds making it unsafe to unfurl the untensioned canopy. Luckily for all involved a break in the weather allowed Base to complete the install just in time – for Portrush the show can well and truly go on.

A sweeping, shell-like fabric canopy embraces the amphitheatre to lend shelter to both performers and tourists. The two main inclined masts support the fabric canopy, reflecting the maritime history of the location.

Rachel House in Kinross is owned by the Children’s Hospice Association Scotland (CHAS). The primary function of this charity is to offer their services free of charge to children with life-shortening illnesses and also support for their parents.

This barrel-vaulted fabric form ‘Jura’ from our pre-designed range, is suspended in a bird-wing style steel frame to form a striking entrance canopy. All the rainwater is collected and diverted to ground via the galvanised steel columns.

Silicon coated Glassfibre fabric was specified as it offers many benefits over its PVC counterpart. It displays a very high degree of translucency at 40%, a lifespan in excess of 30 years and is flame retardant to the highest UK standards achieving BS476 parts 6 and 7.

This canopy has been designed with the future in mind and as such it will provide this very worthwhile charity a high quality structure for the many years to come!

Our client was looking for a demountable wall system to their new exhibition hall structure built to house the National Cold War Exhibition.

We designed, manufactured and installed the fabric panels and the associated steelwork. We also installed the steel framework and trusses.

The tensile fabric structure fulfills a practical purpose as removable walling, as well as being a dynamic use of interior space allowing light into the building.

As the second project for Sainsburys, printed TEXO fabric cladding has proved popular with the client, not only for the impressive speed of installation due to off site assembly, but also the ability to customize the fabric cladding with architectural graphics.

Working for our partners, Aura Custom, we utilised our inhouse wide format UV printers to print 119 tensile fabric panels. The design by Unit Architects consisted of an overcladding using steel reinforced pvc/polyester mesh tensioned onto TEXO frames developed by Italian company Tensoforma.

Covering a total of 2,000 m2 the graphic panels are used as fabric cladding to a car park as well as being carried over into the cladding of the supermarket itself.

The ‘Lilas’ leaf and petal design on the fabric was by the Pitzker-Prize winning architect, Zaha Hadid. It is 5.5 meters in height and is formed by three identical tensile fabric parasols arranged around a central point.

The clients brief was to pattern, manufacture and install this unique tensile fabric structure as a focal point for the Serpentine Gallery’s ‘Summer Party’.