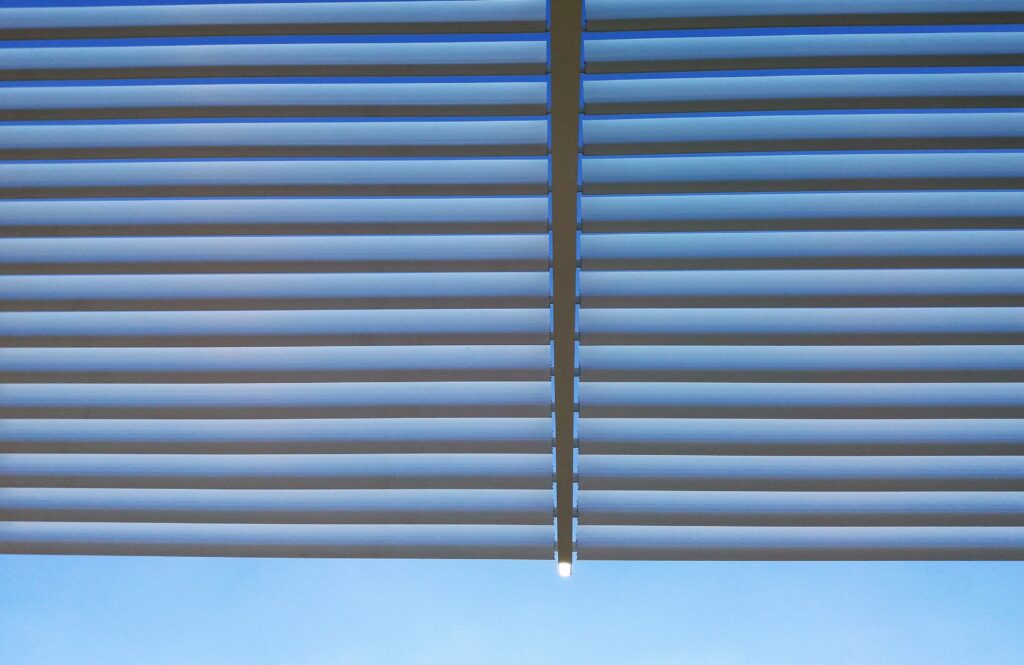

Lord’s Cricket Ground required a new awning to the Grandstand roof to replace the existing retractable blinds over the seated area. Following on from previous works we carried out for the MCC to their Mound Stand and Pavilion canopies, we assisted them in developing a louvre scheme to provide the necessary sun shading and give the stand a fresh look.

The new scheme consists of 384 light-weight aluminium louvre blades in bays of 16 and has been designed to reduce snow and wind loads. A solar survey was also carried out to calculate the optimum angle for the blades to prevent direct sunlight passing through onto the spectators below, whilst allowing maximum ambient lighting.

Due to the precious & hallowed Lord’s outfield, particular care was taken whilst our works were carried out. Light weight Spider MEWPS were deployed to reduce the impact and point loading on the pitch grass.

This is an exciting addition to our portfolio and showcases the extensive design and build knowledge we have in house that enable us to provide custom solutions for special projects.

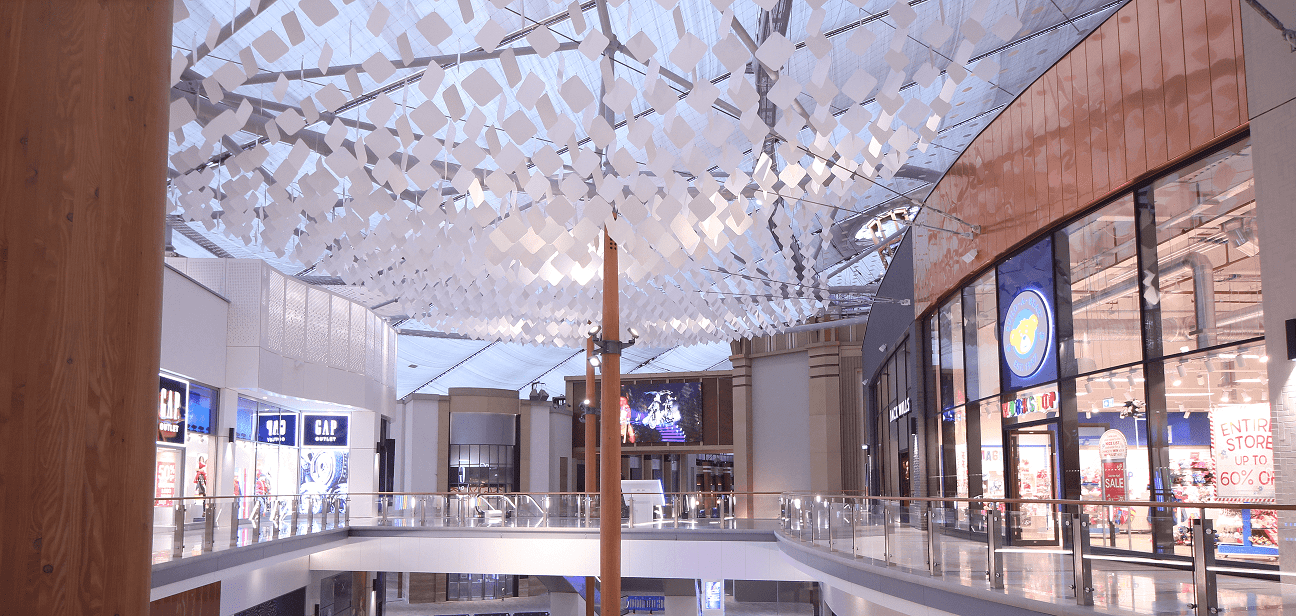

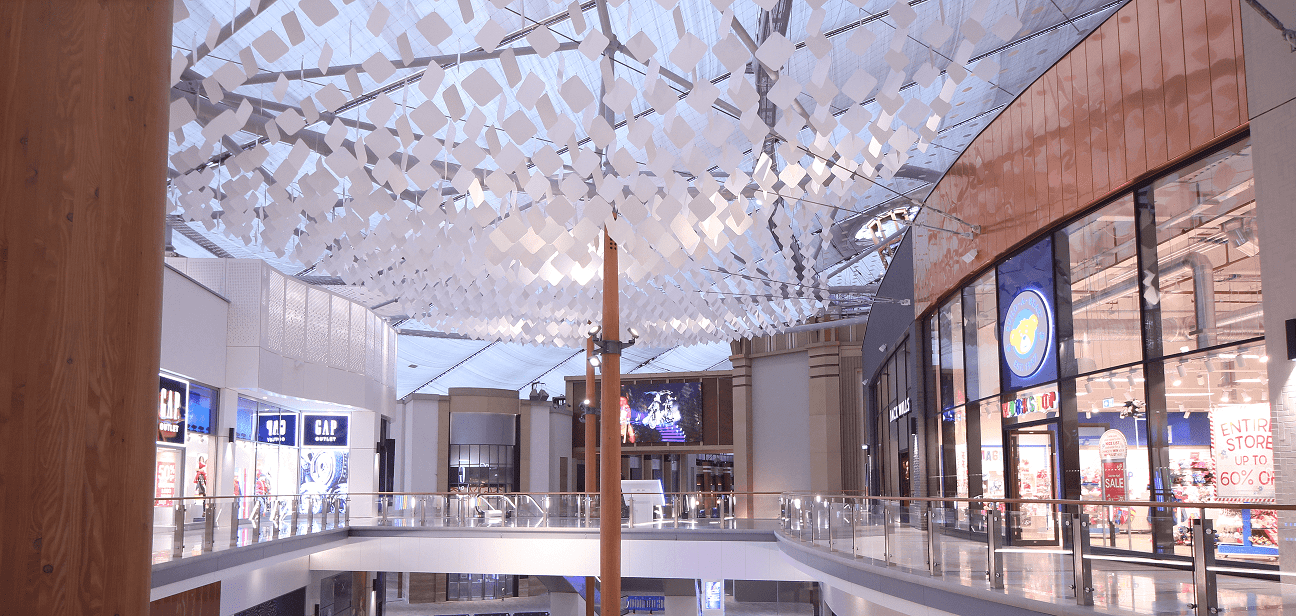

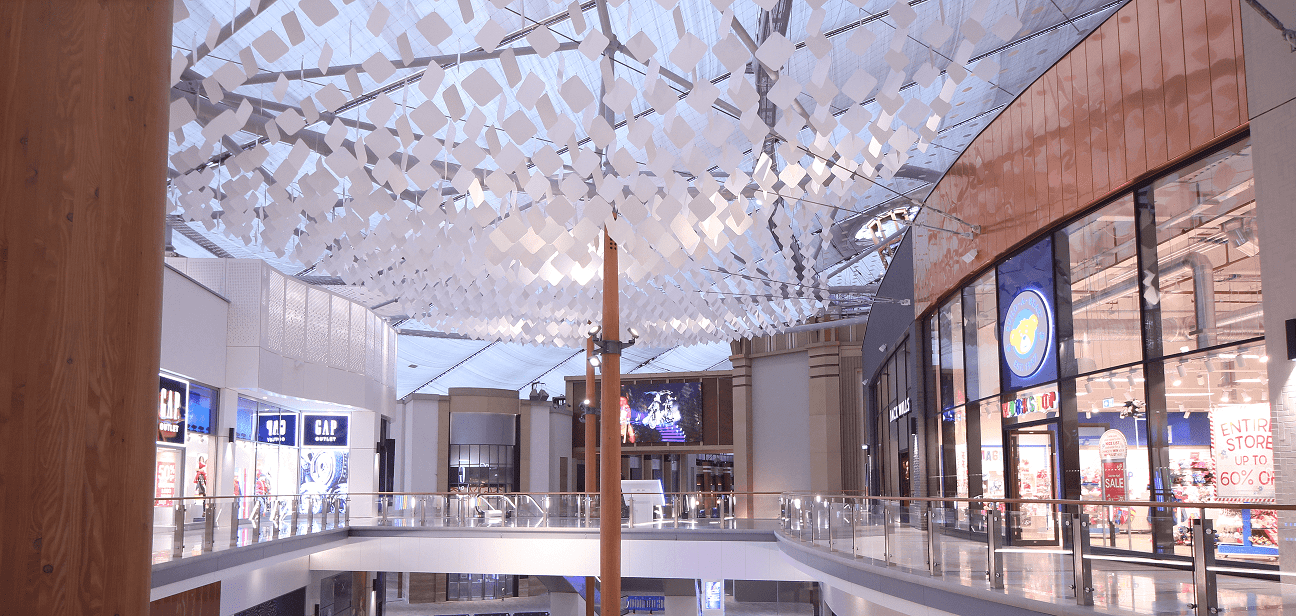

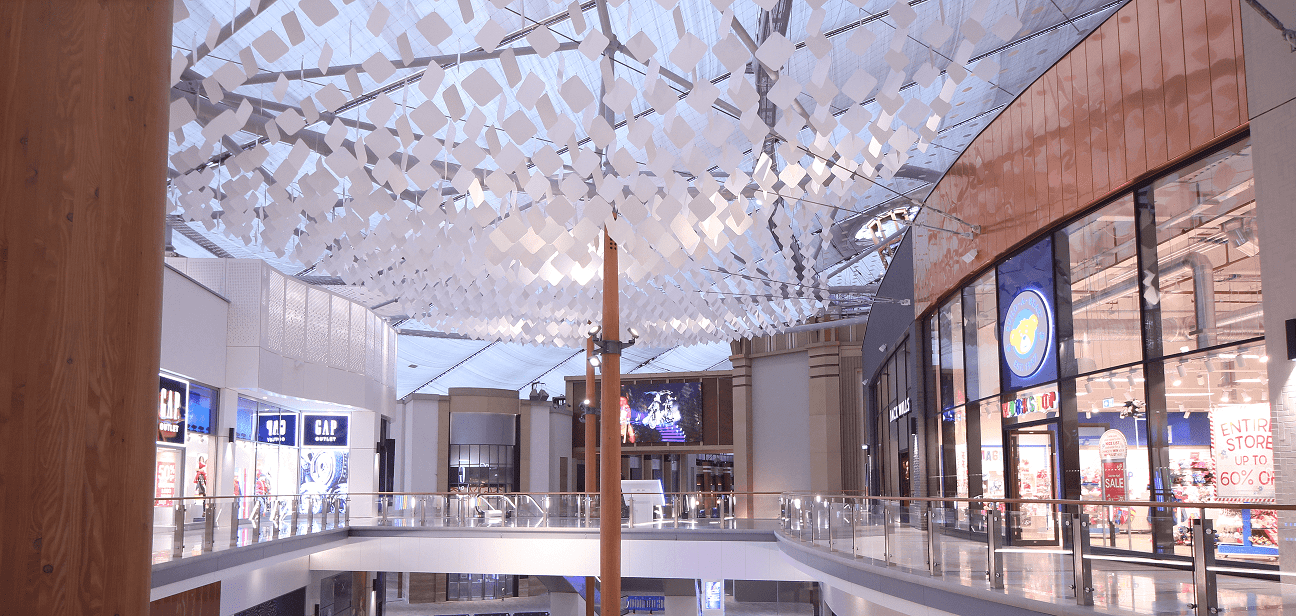

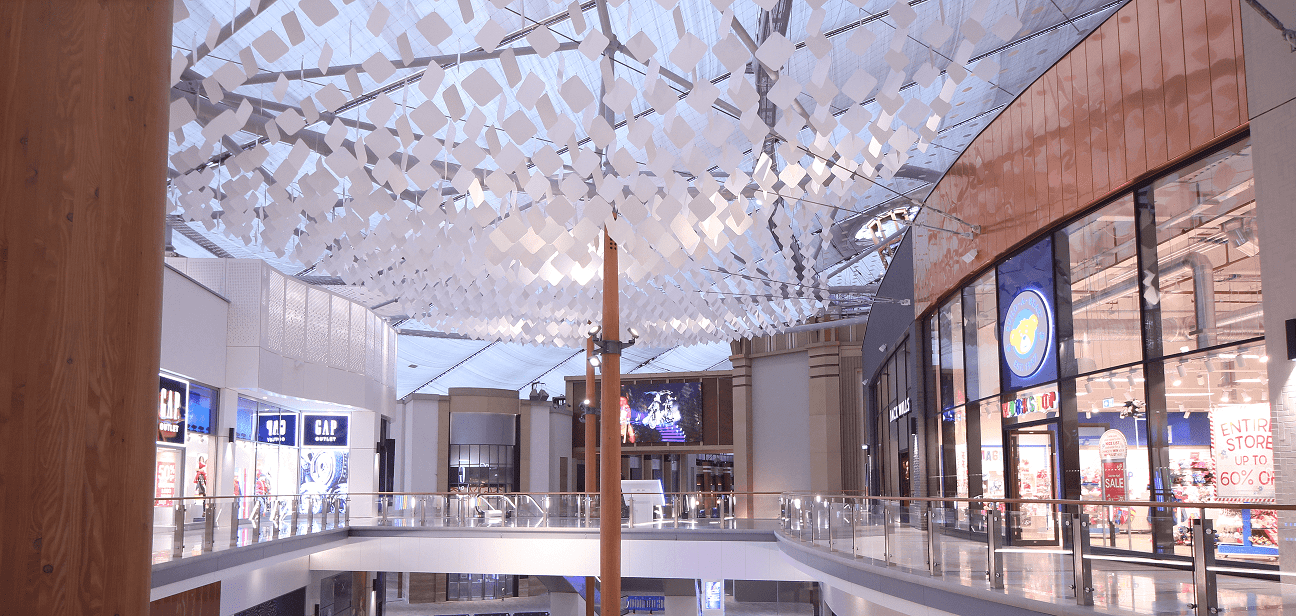

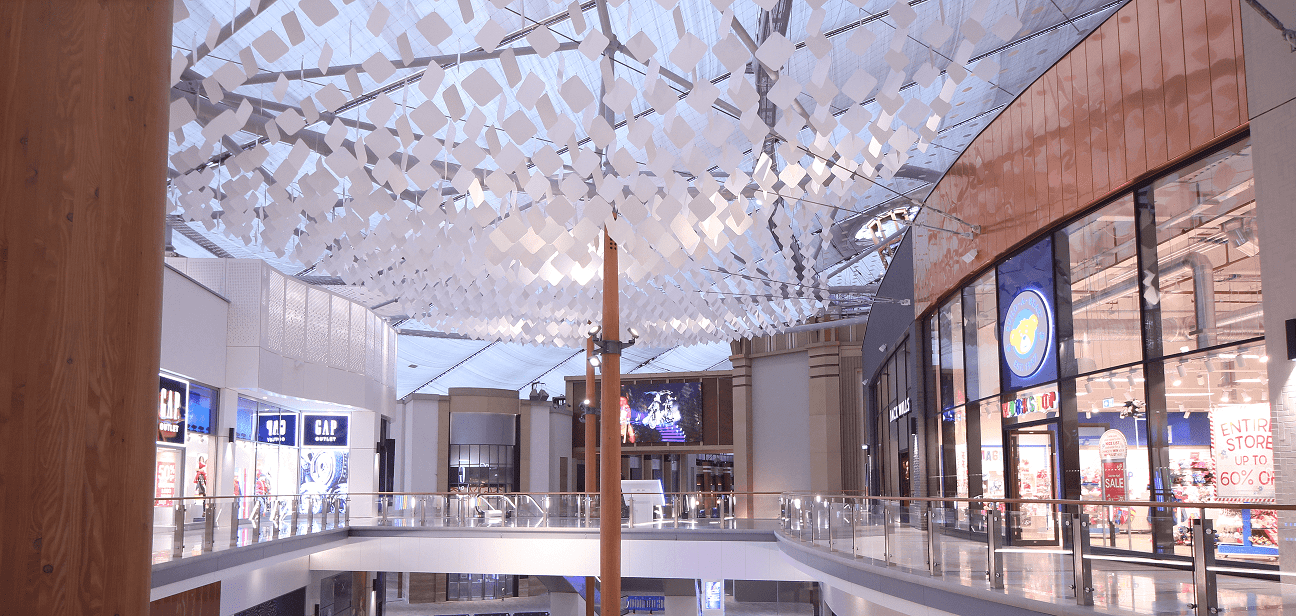

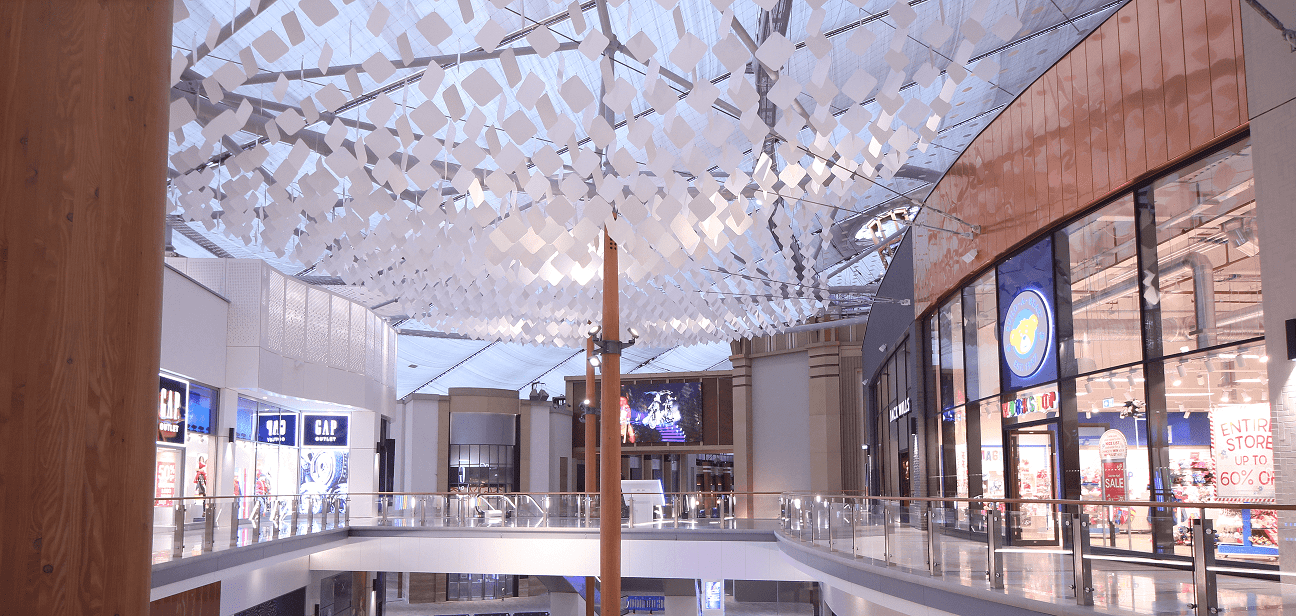

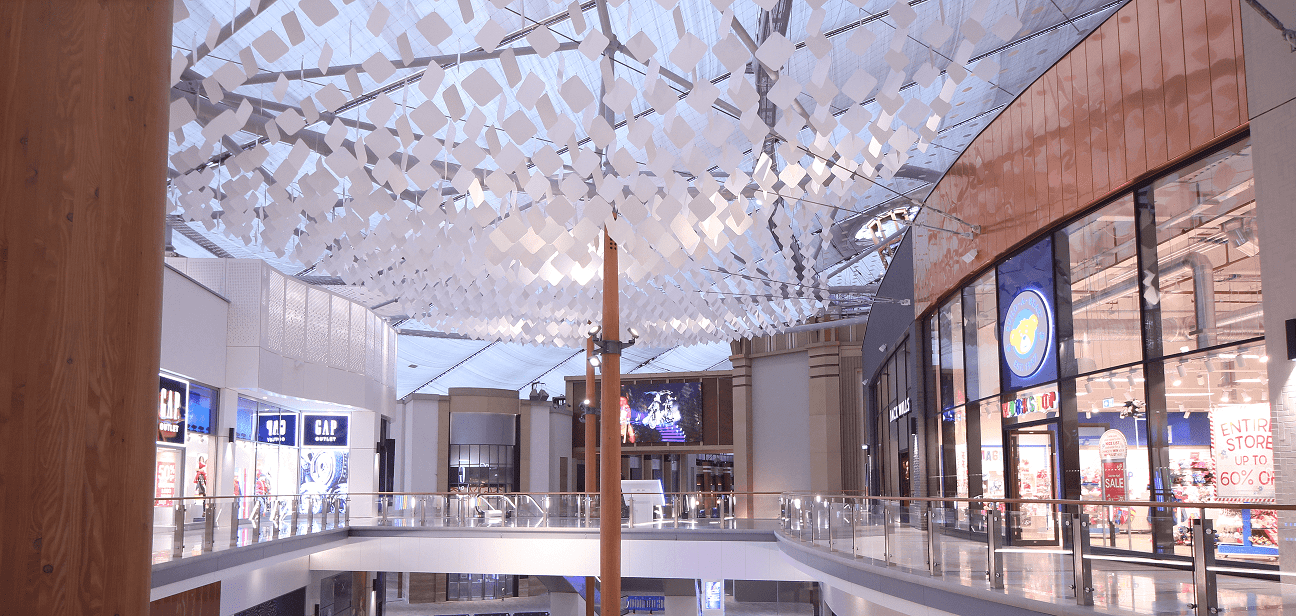

Base Structures recently helped bring to life the street walkways of the O2’s new retail development, the Designer Outlet Village. A total of 8 canopy masts were positioned in its walkways, with 4,744 aluminium white diamond petals and 5300 white discs in two sizes suspended from stainless steel tensioned nets.

The final result is a stunning decorative ceiling giving the mesmerising impression of hanging petals, with the ‘tree trunks’ created using glued laminate beams.

We’re proud to be involved in such a unique project, working with a team over the course of 11 weeks to design, prototype and see the project through to a high-quality installation. We are really happy that the results speak for themselves, and visitors to the O2’s new Designer Outlet Village are now greeted with an impressive feature and visual effect that we hope will put a smile on shopper’s faces for years to come.

We are excited to announce a new city dressing service designing, creating and installing stunning displays in town centres and retail areas around the country.…

Our brief was to provide a spectacular bar for VIPs and artists to service the O2 Venue. The fabric structure consists of four interlocking domes, two entrance tunnels, one of which encloses a staircase, and three conical column claddings.

Barrisol was specified as an ideal material to cope with the complex architectural geometries of each panel. The fabric in the domes is back lit and LED lights are built into the tunnel frames. Base Structures coordinated the complex design and detailing of the scheme and provided the steel frame onto which the Barrisol panels were fixed.

The ambitious design was fully realized to provide a unique chill out zone.

The South Plaza is a 10 hectare site located between the Olympic Stadium and the Aquatics Centre, re-landscaped after the Games by James Corner Field Operations (responsible for the successes of the New York Skyline landscaping project).

Base were tasked with installing a steel cable system to suspend 86 perforated steel lighting globes inherited from the Olympic Games. Running the length of a tree lined boulevard the cables will eventually be virtually invisible within the tree canopies as they grow over the coming years, creating the illusion that the globes are floating above the walkway.

Two pairs of tensioned steel cables are used to suspend each globe, connected to steel masts carefully positioned between the trees in such a way that they blend into the landscaping. The effects at night are certainly dramatic when the glowing orbs highlight the route for pedestrians.

Originally used as a thoroughfare for spectators on their way to the Olympic Stadium, the South Plaza now boasts illuminated tree lined boulevards, play parks, a small performance amphitheatre and benches aplenty.

Built on the site of a former paper mill, this major new housing development in Waltham Forest provides a much needed mix of private sale, shared ownership and market rental homes to help ease the significant shortage of affordable housing in the Capital.

Part of the new build design included a spacious communial atrium that required discreet protection from the elements. A lightwieght single skin ETFE roof was specified that allows 97% light transmittance to penetrate through to the living space below, allowing significant savings of materials and cost. Measuring 39 metres in length and 7 metres wide, the ETFE roof is divided into bays measuring approximately 5.5 metres x 7 metres. Tensioned cables attached to the structural main beams ensures adequate support of the ETFE panels in high-loading conditions such as snow. The only problem with the perfectly tensioned ETFE film is that it is so discreet, most people won’t notice all our hard work!

Having completed the construction of the two iconic No. 8 Towers at Stratford’s East Village, Mace required removal of the temporary fabric cladding that had been used during the build to provide sheltered working areas.

Base Structures UK planned and executed a comprehensive and safe method of work for the dismantling of the PVC screens and associated fixing from these two soaring 113m and 127m high towers.

We provided a team of expert fabric technicians Rope Access personnel who specialise in working at height to set about removing the fabric panels.

Before the removal of the temporary screens, we had worked with the client at the design development stage of the fabric wrap under a pre-contract service.

As the second project for Sainsburys, printed TEXO fabric cladding has proved popular with the client, not only for the impressive speed of installation due to off site assembly, but also the ability to customize the fabric cladding with architectural graphics.

Working for our partners, Aura Custom, we utilised our inhouse wide format UV printers to print 119 tensile fabric panels. The design by Unit Architects consisted of an overcladding using steel reinforced pvc/polyester mesh tensioned onto TEXO frames developed by Italian company Tensoforma.

Covering a total of 2,000 m2 the graphic panels are used as fabric cladding to a car park as well as being carried over into the cladding of the supermarket itself.

The ‘Lilas’ leaf and petal design on the fabric was by the Pitzker-Prize winning architect, Zaha Hadid. It is 5.5 meters in height and is formed by three identical tensile fabric parasols arranged around a central point.

The clients brief was to pattern, manufacture and install this unique tensile fabric structure as a focal point for the Serpentine Gallery’s ‘Summer Party’.

The centrepiece of the new Winton Gallery at London’s Science Museum is a trio of fabric pod sculptures clustered around the tail and wings of a vintage Handley Page aircraft.

The organic fabric forms and the layout of the surrounding gallery are an interpretation by Zaha Hadid Architects of the airflow vortices that would be generated by the plane.

We installed the complex structures, each consisting of a curved aluminium tubular frame suspended from the ceiling onto which two skins of semi-translucent PVC coated polyester are tensioned.

Multiple LED lighting strips are mounted between the skins and contribute to the stunning overall effect. Due to the complexity of the structures, one of the twin skins had to be split and fed through the apertures created by the other skin before being joined together with two hidden zips.

The tensioning system is hidden behind double curved aluminium cover plates.

Base were also responsible for the installation of the interpretation surfaces adjacent to each exhibit.

Image credits: © Nick Guttridge

Our brief was to install temporary wraps to the columns at the entrance of Tate Britain, as a special feature linking in with the David Batchelor artwork exhibition taking place at the time. The wraps acted not only as an advertisment for the exhibition but were a vibrant and imaginative use of the existing buildings architecture.

The project was more complicated than it looked as each natural stone column is unique and therefore each one had to be individually surveyed by our climbers before patterning the fabric to suit. We manufactured the wraps from fabric printed to the colours specified by the artist and installed them at night, once again using ropes access techniques. The Tate Britain Museum were extremely pleased with the result of the finished product and the high quality.