London’s Camden Market’s carnival atmosphere famously attracts people from all walks of life and is popular with Goths and Punks who live and work alongside the traditional antiques and clothing traders. Due to increased visitor numbers, this borough of London has recently attracted substantial development funding enabling a gradual and sympathetic facelift to take place. How apt that this beautifully crafted walkway canopy should adorn a building that sits at the heart of London’s bohemian arts and crafts district.

We decided to use Tenara material which is 100% PTFE and is manufactured to very high quality standards. Accordingly, it benefits from high levels of translucency such that the light striking the smooth curves of the canopy is evenly diffused, lifting the whole structure and making it appear to fluoresce. The twisted, eccentric steel framework which carries the fabric is constructed of many irregular curves making the geometry of each bay completely unique. Needless to say the patterning of the fabric was a monumental task, and yet it fits so well.

Set as it is against a backdrop of muted coloured glass curtain walling set in steel grey frames, this installation promotes the fabric so that it appears to shine like a pearl unearthed in this most unlikely of habitats. The completed project is a true testament to the combination of visionary artist and engineer.

The spectacular Cutty Sark deserves to welcome its visitors in a spectacular venue. Therefore, this multi-cone tensile fabric structure had to be one of the most unique architectural fabric creations in the country. By day, its peaks resemble crisp meringue; by dusk, the detail in the beautifully lit cones truly comes alive.

The seventeen tensile hexagonal cones have a unique relationship with their timber grid below. In short, one cannot survive without the other. The fabric locks the grid in place, providing the awesome strength needed to hold this beautiful beast in place. A true example of collaborative working processes, from conception to completion, the engineering, timber and fabric all had to work in perfect harmony.

Conceived by innovative architects Youmeheshe, the fabric structure strikes an arresting mark on the landscape. It is not just its visual form that breaks new ground.

Every year a covered green space in which to relax is generated within London’s famous Square Mile as a place where executives and their clients can go to view dinner time theatrical and musical events. Base Structures were commissioned by the client to replace the existing tensile fabric covers in Exchange Square, which were starting to look tired.

In order to reproduce the existing covers Base Structures design department had to survey the steel and cable net structure from which they could generate the ‘form’ of the new structures.

As you can see from the pictures, this was achieved very successfully and the new fabric structure once again looks fit for purpose.

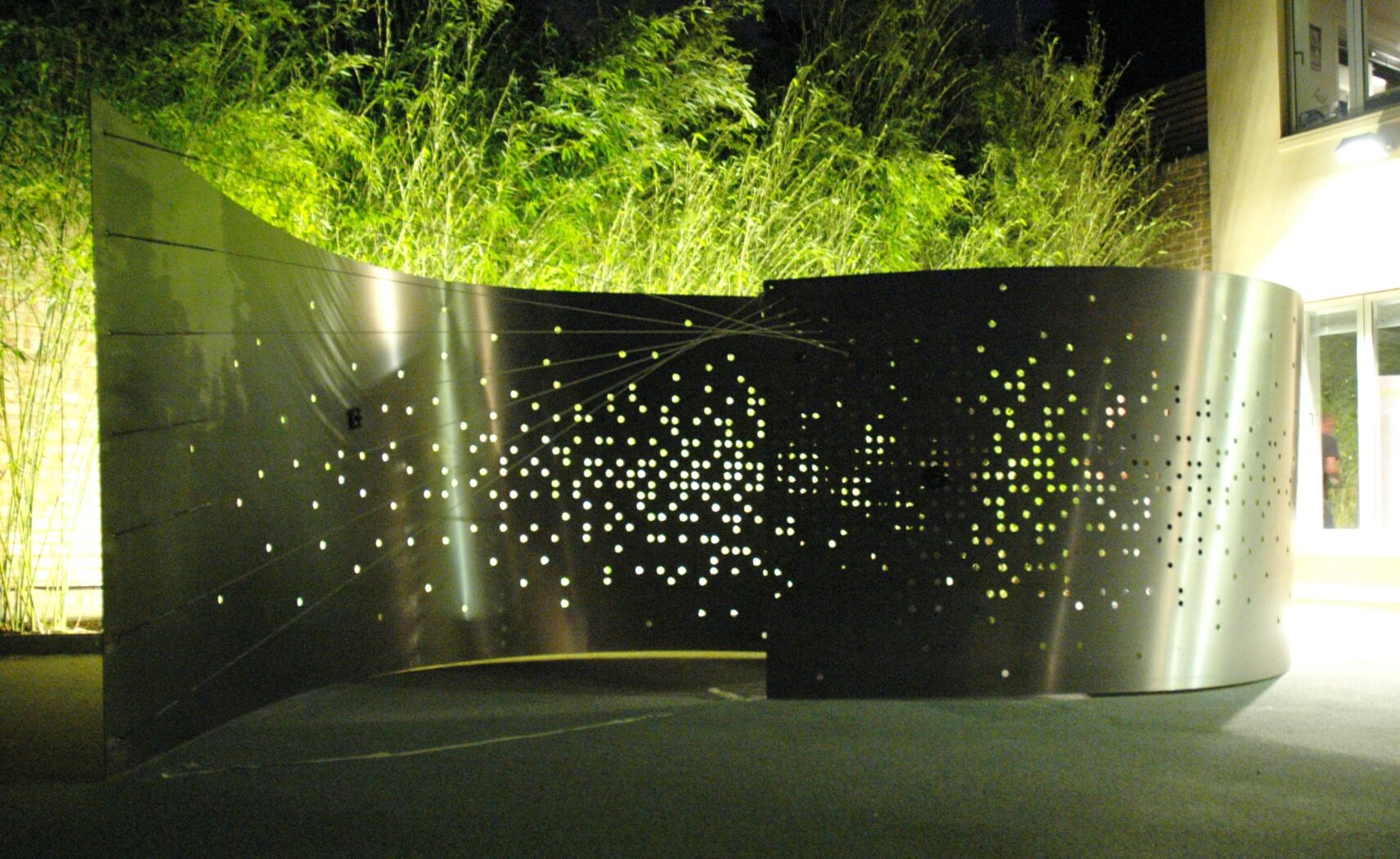

This curved stainless steel structure was conceived by LDS for Architecture Week, it was fabricated and installed in Exhibition Road for the day then moved and permanently reinstalled at the architects practice in the evening following the exhibition.

Base Structures provided detail design input, fabricated and installed the structure and dealt with the site logistics, all project managed by Mark Smith.

This new restaurant in the high profile area of Camden required a retractable roof system for open air dining in the summer months. The tensile fabric membranes needed to allow natural light into the restaurant when the roof is closed, enhancing the interior space as well as being a dynamic feature.

We designed, manufactured and installed the motorised retractable roof system and the fabric membrane.

Home to Dim sum, sushi and cocktails, the roof system perfectly compliments the elaborate Indian-chic setting with wood carvings and an open kitchen.

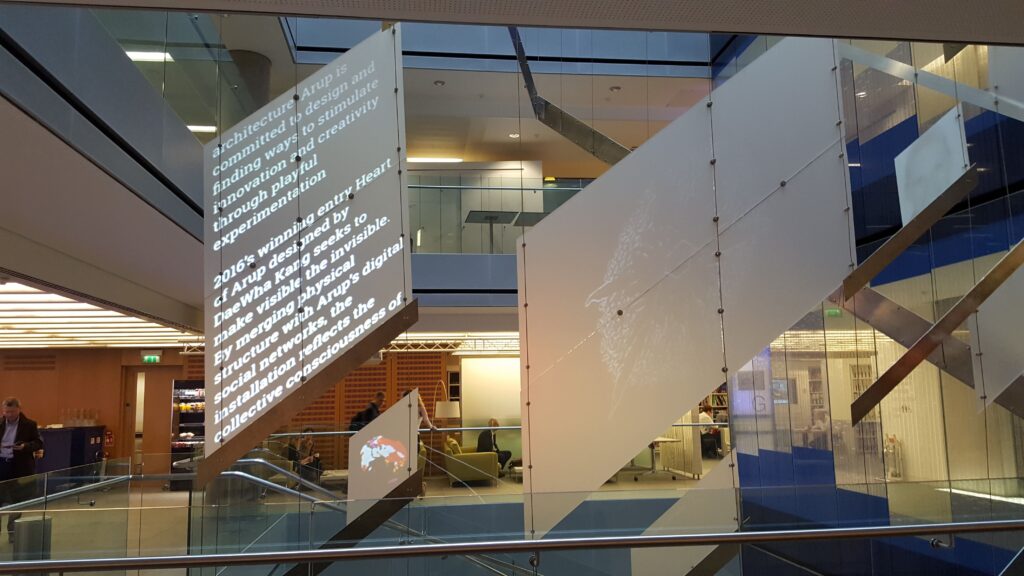

As one of the world’s largest engineering consultancy practices, Arup commissioned a futuristic design, merging the digital world into physical architecture. Following the No.8@Arup competition and DaeWah Kang Design’s winning entry, “Heart of Arup,” Base were approached to source, supply and install this innovative art installation.

Forging a relationship with the design team, Base was approached to source, supply and install the stainless steel cable system and aluminium stretchers for this exciting project. Our challenge was to develop a suitable design for the project that not only met the budget constraints, yet was also delivered to an extremely tight deadline for the installation – within one weekend! After successful completion, Arup is now able to experiment with the installation and we’re excited to see what this could mean for the future of media architecture.

The Heart of Arup is an interactive multimedia experience that now gracefully hangs within the atrium space at Arup’s global headquarters in London. Social media feeds from the company’s network, Yammer, and is visible within the six storey office. The art installation can be seen from many different points within the building, encouraging a natural form of communication from both public and working spaces.

Although our client was sited in a campus of high architectural quality buildings there was a desire to introduce more informality in order to improve the working experience.

Alongside the introduction of a fabulous coffee cart, meeting pods and nature inspired wall graphics we were asked to provide an array of suspended leaves in their three storey atrium. To avoid a forest of suspension cables a stainless steel net was tensioned between columns at high level allowing each leaf to be on a single drop cable.

The leaves were UV ink jet printed with designs representing the changing colours of the seasons and were grouped in three arrays. The fabric selected was a PVC coated glass cloth mesh that has acoustic properties helping to keep noise levels down for those enjoying the newly invigorated space.

Stunning architecture has become a trademark of the modern Olympic and Paralympic Games, with environmental credentials being of paramount importance. As such these three structures are not only at the forefront of contemporary design, they are also fully demountable and relocatable, amply fulfilling these criteria. Together they hosted the Shooting, Paralympic Shooting and Paralympic Archery events. The set consisted of the 25 meter, Combined 50 & 100 meter and the Finals Shooting Ranges.

Each event structure is individually identified by the bright discs of colour which are set into the high and low points that create the undulations in the facades. The Orange themed Finals building measures in at a massive 25m x 47m x 50m, requiring 16,000m2 of fabric to fully clothe it inside and out. The Magenta themed Combined Range measuring 10m x 20m x 106m, requires 9,000m2 of fabric and the blue themed 25m Range building measuring 25m x 55m x 10m, 5,000m2. The high level discs incorporate ventilation openings whilst the ground level ones identify doorways for ingress through similarly coloured tunnels to the sporting arenas.

IFAI International Achievement Award 2013 Winner.

The critically endangered Sumatran tiger is one of the rarest subspecies of tiger with a remaining wild population of approximately 300 individuals. Due to a combination of poaching, habitat loss and human conflict the Sumatran tiger population has suffered a staggering 95% decline in the last decade, placing it at high risk of extinction on the IUCN Red List.

ZSL London Zoo have been working across the globe in a major effort to improve the fate of the Sumatran tiger, culminating with a new flagship ‘Tiger Territory’ facility. Not only enabling the zoo to embark on a critical breeding programme, ‘Tiger Territory’ also allows experts to gain valuable information about the elusive creatures that can be applied to conservation projects in the field. Tiger Territory is intended to be a centre to match-make Sumatran tigers from around the world, with the first inhabitants scheduled to be Jae Jae and Melati. Selected by the global breeding programme for the critically endangered species and prized as Europe’s most genetically important pair of Sumatran tigers, their cubs would be the first to be born at ZSL London Zoo for over 15 years.

Robin Fitzgerald, Project Manager, ZSL London Zoo

Harry Everest, Project Manager, ZSL London Zoo

Mike Kozdon, Architect, Wharmby Kozdon Architects

Gavin Sayer, Associate, Dexter Associates

Andy Traynor, Head of Installation/Director, Base Structures

Andy Chiverton, Project Manager, Base Structures

For a project of such global significance the stakes were high for the new zoo structure. The primary focus was on animal welfare, conservation and the creation of the perfect environment for animal husbandry – rather than the creation of an architectural masterpiece. As Robin Fitzgerald, Project Manager at ZSL London Zoo summarised ‘Our goal was to seek out the latest technologies and designs that could match our husbandry and habitat requirements while still satisfying visitor needs.’

Key objectives were set out with a team of conservationists, tiger keepers and education specialists. From a habitat perspective the zoo enclosure clearly needed generous proportions, especially in height – the Sumatran tiger is a keen climber with a preference for observing its terrain from a high vantage point and can boast an impressive vertical jumping ability of up to five metres. The facility also had to meet strict husbandry requirements and be practical for everyday zoo keeper use. Capacity for future additions had to be factored in as well as the sustainability and energy efficiency of the enclosure. From a visitor perspective it was vital to offer a spectacular viewing experience with multiple perspectives, including a prominent, highly visible platform for the education department to deliver talks. All of this needed to be achieved within the existing constraints of the 186 year old site and adjacent architecture.

A team was assembled to turn this vision into reality that included Mike Kozdon of Wharmby Architects and specialist consultants including Base Structures and structural engineers Dexter Associates. Collaborating closely with the zoo, the team could apply the specialist knowledge that is necessary to turn the brief into not only a workable concept, but a flagship zoo enclosure.

A woven mesh structure was designed that could mould itself around the existing footprint shape and soar upwards into peaks, providing the necessary vertical jumping space. This design was not simply a response to the existing site geometry however. 90° angles were carefully and deliberately designed out to present sloping, organic lines to better reflect nature. A 3mm diameter cable woven 316 stainless steel mesh was selected with a 100mm x 100mm aperture – aesthetically the mesh would provide a thrilling experience for the public by virtue of its unobtrusive appearance. Floor to ceiling glass viewing panels topped with a fabric canopy would also allow the public to stand within millimetres of the tigers.

Tiger Territory was intended to be ultimate big cat exhibit for both visitors and the cats themselves. The dramatic form of the zoo enclosure creates a wonderful sense of drama when approaching Tiger Territory through the zoo grounds, yet the unobtrusive mesh allows the enclosure to simply fade away into the background when the tigers are viewed at close quarters. ZSL London Zoo’s brand new Sumatran tiger enclosure was given the royal seal of approval on Wednesday 20th March 2013, when it was officially opened by HRH The Duke of Edinburgh.

The Sumatran tiger enclosure was given the ultimate seal of approval on the 3rd February 2014 when a trio of healthy cubs were born to five year old Sumatran tigress Melati. Hidden cameras in the cubbing den allowed the zoo to remotely monitor the birth and the progress of the cubs 24 hours a day, with exclusive footage released on the ZSL You Tube channel (www.youtube.com/user/ZSLvideo.). The births are not only a huge achievement for ZSL London Zoo but also the international breeding program.

Lords cricket ground, owned by Marylebone Cricket Club, is regarded as the world wide spiritual home of cricket. To ensure the Ground remains not only world-famous but a truly world-class sporting venue, a multi-million pound overhaul was undertaken, part of which included the upgrade of the Mound Stand canopy which after eighteen years of sterling service had reached the end of it’s designed life span.

John Cutlack, Director Capita Symonds

Tony Hogg, Director, Tony Hogg Design Ltd

Mark Smith, Contracts Director, Base Structures

Chris Ives, Project Manager, Base Structures

We were briefed by Capita Symonds, the appointed representatives of Marylebone Cricket Club, to remove, redesign, manufacture and install the new tensile fabric roof over the Mound Stand, a monumental task that would not simply replace the old canopy but provide significant structural improvements through the use of more advanced materials and up-to-date design detailing. As such the replacement canopy would be expected to last significantly longer than the old one.

A fundamental part of the contract win was our ability to ensure the recycling of the old canopy and so we partnered with Serge Ferrari (suppliers of the fabric for the new canopy), who have developed and built the Texyloop PVC recycling factory in South Eastern France. The recycling of the old canopy led to Base Structures achieving a finalist Building award for Sustainability in 2006.

Base Structures were able to provide the client with a methodology that ensured we would meet the tight deadlines, budgets and planning restrictions. This was made possible through the accurate surveying of the existing structure to ensure the replication of the iconic shape, and through the use of innovative access methods. It was essential that the project was undertaken and completed in one closed season so that our works did not interfere with or delay scheduled cricket matches.

The first task was to remove the old canopy, in itself a huge job. The biggest problem faced by our team concerned how to fully access the canopy structure as it overhangs a busy main road and is closely neighboured by residential buildings.

The solution we identified required the use of Working Platform Nets. These netting systems are engineered to ensure the safety of the operatives working on and below them is not compromised and they proved to be incredibly cost effective by reducing the man hours needed working at height, when compared to traditional means of access such as scaffolding. Once the netting was installed by our fully qualified rope access team, non-IRATA trained personnel could then access the work areas in complete safety. The old canopy came down surprisingly quickly once the netting allowed easy access to the structure, especially considering the amount of fabric involved.

Next a detailed survey of the existing steelwork enabled our design department to accurately recreate the iconic structure within our specialist CAD software, from which we produced the cutting patterns and finalised the detail design.

It was necessary to redesign and upgrade all the fixtures and fixings on the existing structure to take into account advancements in tensile fabric over the previous eighteen years, ensuring that they were all brought up to current best practice standards. The new PVC membrane itself was a higher specification fabric than the original canopy, using higher quality PVDF lacquers to guarantee a longer life span. As part of this extensive upgrading process all the existing structural steelwork was repainted before the new canopy was installed.

The old canopy was originally made in sections that were joined together using metal fixtures. Taking advantage of the opportunity to redesign the canopy and to improve the aesthetics, the new 1400 sq metre fabric membrane was manufactured and installed as a single piece of fabric. This improvement resulted in no site joints along the front of the canopy, significantly enhancing the overall appearance.

Once manufactured the installation of the new canopy began in earnest; the fact our rigging team had removed the old canopy gave us a flying start when it came to installing the new one, since they already knew the structure inside and out. After the new canopy was lifted over the multiple masts in one piece, our rigging team made short work of the installation.

The entire project was successfully completed ahead of schedule and below budget, no easy task considering the scale and complexity of the project. The replacement canopy not only restored the stand to its former glory but also improved the aesthetics and expected life span of the structure. Marylebone Cricket Club were extremely happy with the refurbishment and continue to use Base Structures for regular maintenance of this most iconic of structures.