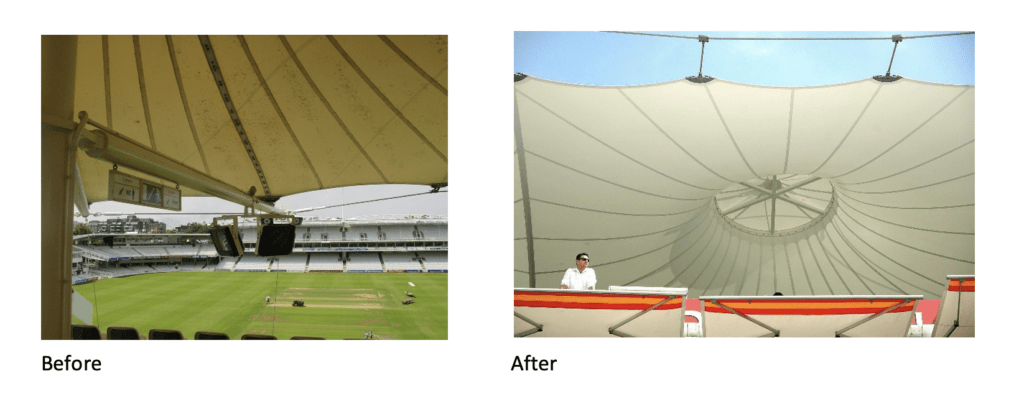

Many of the UK’s fabric structures that were installed before the millennium are nearing the end of their design life and as such owners may be considering replacement canopies. Here at Base we have replaced several landmark fabric structures, in this blog we want to explore the sensitive process of replacing a well established structure to give it a new lease of life whilst preserving the identity and design features. We have done this by focusing on one great example of this, replacing the Iconic Lords Mound Stand Canopy.

The spiritual home of cricket, Lords, can trace its roots as far back as the late 18th century. As one of the founding venues of the game, it’s an impressive icon for the sport, and needs thorough maintenance to be kept in perfect shape all year round. Owned and run by the governing body of cricket, the Marylebone Cricket Club (MCC) commissioned a multi-million pound overhaul of the venue back in 2005. Base Structures were on-hand to help replace the ageing canopy over the Mount Stand – which was due an upgrade after nearly twenty years in service. Read on to find out more about how we did it.

The decision to replace a canopy is not a decision taken lightly, but in this instance, a new canopy was deemed to provide significant structural improvements due to the use of new material and would be expected to last a significantly longer time than the previous one. Because of this, we were appointed to provide a methodology that kept to strict budget and timeline requirements, incorporating into our solution innovative access methods that caused minimum disruption to ensure that scheduled cricket matches wouldn’t be impacted at the start of the season.

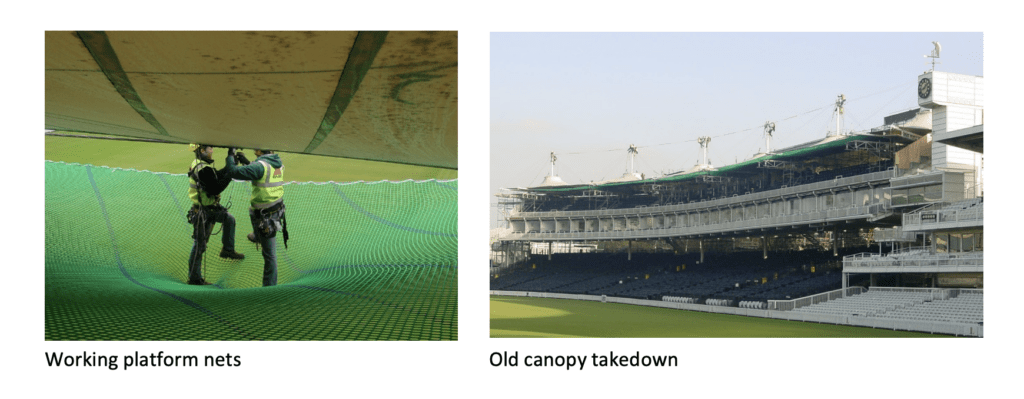

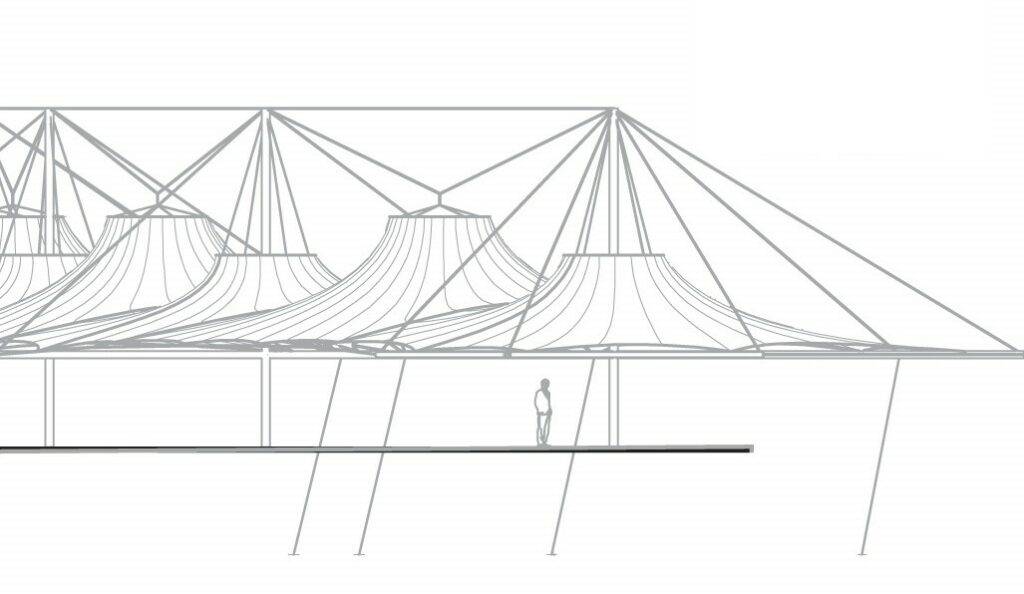

As with any of our replacement canopy projects, to provide the best possible outcome we ensured we carried out an extensive and thorough survey of the whole site. This meant we could plan a solution to replicate the iconic shape, assess the best access methods to minimise disruption to local transport and additionally to ensure the structure was suitable and in good enough condition to hold the weight of a new canopy.

We also had to work out how we were going to remove the old canopy. Our survey identified that working platform nets were the best way of ensuring safety whilst working at height – these solutions offer excellent flexibility and safety compared to traditional scaffolding, and meant that once certified by our rope-access team, non-IRATA trained personnel could work on them – significantly expediting the replacement process.

With the survey of the existing steelwork structure complete, we could use CAD software to accurately map out, design and plan a replacement fabric. We did improve the canopy design for the new installation by making the fabric in one single piece, whilst still preserving the familiar shape of the canopy, this change would improve the overall aesthetics and required our full fabric expertise to plan the methodology for installation.

We didn’t just deal with the installation, we also ensured that all steelwork was painted and touched up before installation, and that all fixtures and fitting were brand new to ensure total safety. Of course, the replacement fabric we used was also of a far higher specification than the old one due to many technical advancements over the years and has a greater expected design life than the previous of 25-30 years.

One key area of this project that we carry over into as many replacement canopy projects as we can is sustainable and ecologically sensitive disposal of the old fabric. Making sure we send as little to landfill as possible is an important part of our role and not one we take lightly – for this project we partnered with the fabric’s manufacturer and supplier to send the old canopy to a PVC recycling plant. By doing so, we were also recognised with a building sustainability award! Read more about our approach to sustainability.

As with any replacement canopy project, the Lords Canopy was successful as it was prefaced by thorough survey work, planning, preparation and consideration. It also was a full belt-and-braces approach – we made sure all steelwork was painted and improved, as well as providing and installing brand new fixtures and fittings. Contact us today to discuss how we might be able to help your business by fitting a new canopy – whether large or small.